Single Phase Motor vs. Three Phase Motor: The Complete Guide

30/10/2024

Sam Nie

Hello every one. This is Sam Nie, the CEO of LUPMOTORS. With 10 year's technical and manufacture experience in the field of 3-phase electric motor, I can provide you definitive guides in the knowledge of 3-phase industrial electric motors,which will help you a lot in selecting electric motors for your applications.

When you are going to choose the right motor, it’s important for you to know the differences between single-phase and three-phase motors.

Whether we’re going to equip a motor for a small appliance at home or a large industrial machine, each type has its advantages and limitations.

In this guide, I’ll introduce you the essentials of both motor types so that you, as a buyer, engineer, or facility manager, can decide which one actually meets your needs.

We’ll explore the pros, cons, and specific applications for each together.

Table of Contents

What is a Single-Phase Motor?

A single-phase motor is an AC motor that operates on single-phase power, which means it uses a single alternating current (AC) waveform.

These motors are popular in residential and light commercial settings.

In single-phase motors, the flow of electricity creates a pulsating magnetic field rather than a rotating one, which limits the motor’s starting torque.

To overcome this, single-phase motors often require a starting mechanism, like a capacitor or additional winding, to initiate movement.

Learn more details of the single phase motors as bellow.

Technical Specifications and Characteristics

Single-phase motors run on a voltage range of 120V to 240V, which makes them suitable for small-load applications.

The power ratings range from 0.25 to 5 HP (0.19 to 3.73 KW). Because they rely on the single-phase AC power, they have lower torque output, which make them just used in low-power-demand applications.

A standard single-phase motor achieves an efficiency of 50-70%, which is lower than the three-phase counterpart.

Common Applications of Single-Phase Motors

Because of their limitations in torque and power output, single-phase motors are widely used in low-load applications where continuous heavy-duty performance isn’t required. You’ll often see these motors in:

Household Appliances

Washing machines, fans, and refrigerators commonly rely on single-phase motors, and other appliances which don’t require the industrial-grade power.

Light Commercial Equipment

Single-phase motors are also used in small air compressors and other low-demand machinery

HVAC Systems for Residential Buildings

Smaller HVAC units in homes frequently use single-phase motors due to their lower power needs.

Pros and Cons of Single-Phase Motors

Pros

Cost-Effective

Suitable for Home Use

Simplicity in Design

- Cost-Effective: Single-phase motors are generally more affordable than three-phase motors, both in purchase cost and maintenance.

- Simplicity in Design: With fewer components, single-phase motors are easier to install and maintain.

- Suitable for Home Use: They’re ideal for home appliances and small machinery that doesn’t require high torque.

Cons

Lower Efficiency

Increased Maintenance:

Limited Power Output

- Lower Efficiency: At 50-70%, single-phase motors are less efficient than three-phase motors with more energy consumption.

- Limited Power Output: They provide lower torque, making them unsuitable for industrial or high-load applications.

- Increased Maintenance: The need for additional starting mechanisms, like capacitors, can increase maintenance needs, especially over prolonged use.

Real-World Example

Imagine a 1.5 HP single-phase motor that is used in a home HVAC system.

This motor operates on 120V, and with its efficiency rate of around 60%, it consumes about 1.1 kWh for an hour of operation.

In contrast, a three-phase motor at similar power would operate at 85% efficiency.

That means it will save energy costs for heavy-duty applications.

What is a Three-Phase Motor?

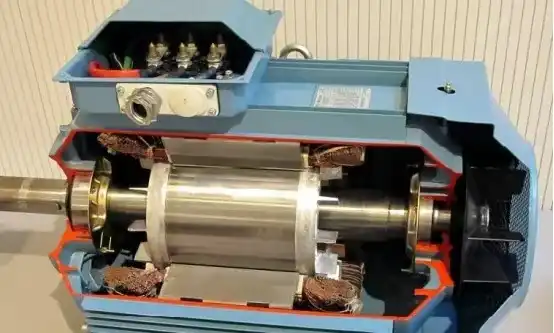

A three-phase motor is a kind of AC motor that use three phase electric power, which are out of phase with each other by 120 degrees.

This creates a consistent rotating magnetic field, which produces smooth, continuous torque.

Three-phase motors can start on their own without additional starter like capacitors.

They are known for their high efficiency and stable performance, making them ideal for industrial applications and heavy-duty operations.

Learn more details of the three phase motors as bellow.

Technical Specifications and Characteristics

Three-phase motors generally operate on a higher voltage range than single-phase motors, often around 208V to 480V in industrial applications.

With a typical power rating starting at 1 HP and reaching up to hundreds of HP, they can support large-scale equipment.

These motors have an efficiency range of 85-95%, which reduces energy loss compared to single-phase motors.

They are also capable of maintaining high torque levels, crucial for demanding applications.

Applications of Three-Phase Motors

Three-phase motors are frequently used in applications that require high power and reliability. You’ll find them in:

1. Industrial Machinery

Three-phase motors power heavy equipment in factories, such as conveyor belts, pumps, and compressors

2. Power Tools

Industrial-grade tools and machines like large drills, grinders, and lathes use three-phase motors to achieve high performance and extended durability.

Large commercial HVAC systems depend on three-phase motors for energy-efficient air conditioning and heating.

Pros and Cons of Three-Phase Motors

Pros

Please slide to read the contents.

Cons

Please slide to read the contents.

Real-World Example

Consider a 10 HP three-phase motor used in a factory conveyor system.

Running at 480V, it operates at around 90% efficiency, consuming less current for the same output compared to a single-phase motor of similar power.

This setup not only saves on energy costs but also minimizes maintenance due to its lower operating temperature and reduced wear.

Key Differences between Single-Phase and Three-Phase Motors

Basic Differences

Understanding the Basic differences between single-phase and three-phase motors is essential for choosing the right motor for specific applications. Please check the following table for your reference.

| Feature | Single-Phase Motor | Three-Phase Motor |

|---|---|---|

| Power Supply | One alternating current (AC) phase | Three alternating currents (120° out of phase) |

| Voltage | 120V - 240V | 208V - 480V or higher |

| Efficiency | 50-70% | 85-95% |

| Torque Consistency | Lower, pulsing magnetic field | High, steady rotating magnetic field |

| Applications | Residential and light commercial | Industrial, heavy-duty, commercial HVAC |

| Cost | Lower upfront cost | Higher upfront cost |

| Maintenance | Higher due to starting components | Lower, simpler maintenance in heavy-use |

Capacitors and Magnetic Fields in Motor Operation

Understanding how single-phase and three-phase motors create motion requires a closer look at two key elements: capacitors in single-phase motors and rotating magnetic fields in three-phase motors.

These mechanisms determine how effectively each motor type initiates movement, maintains torque, and achieves reliable, consistent operation.

Single-Phase Motors and Capacitors

1.Start Capacitors

Start capacitors are designed to provide a quick boost of power by creating a phase shift at start-up. They typically offer 70-300 microfarads (µF) of capacitance, depending on the motor’s size and intended application. For example, a 1 HP single-phase motor might need a capacitor rated at 200 µF to start, creating a rotating magnetic field that initially spins the motor shaft. Once the motor reaches a set speed, the start capacitor disconnects.

2.Run Capacitors

Unlike start capacitors, run capacitors remain connected throughout the motor’s operation. They supply 10-50 µF of continuous capacitance, which stabilizes the current, helping maintain steady torque. This makes the motor more efficient and smooths out operation, although it still won’t match the consistent torque of a three-phase motor.

3.Advantages and Limitations

Capacitors allow single-phase motors to start and run reliably, but they add maintenance requirements. Over time, capacitors can degrade due to heat and wear, potentially leading to start-up failures. Additionally, the pulsating magnetic field in single-phase motors creates vibrations, leading to quicker wear and reduced efficiency compared to three-phase motors, with average efficiencies of around 50-70%.

Three-Phase Motors and Rotating Magnetic Fields

Three-phase motors, on the other hand, achieve rotation naturally through their three-phase power supply.

Each of the three currents is offset by 120 degrees, creating a smooth, continuous rotating magnetic field without the need for capacitors or other start-up components.

Here’s how this works and why it’s beneficial:

1.Self-Starting Rotation

2.Efficiency and Smooth Torque

3.Real-World Example

In a word, single-phase motors need capacitors while three-phase motors do not because of their differences in working principles and structures. Single-phase motors need to simulate the phase difference in three-phase motors to generate a rotating magnetic field, while three-phase motors use the phase difference of the three-phase power supply to directly generate a rotating magnetic field, so no additional capacitors are needed.

Energy Consumption and Cost Efficiency

Single-Phase Motors

Single-phase motors are less efficient and consume more energy per unit of output compared to three-phase motors.

For example, a 1 HP single-phase motor operating at 60% efficiency might consume about 1.6 kW for every hour of use.

In high-usage scenarios, like continuous HVAC or production equipment, this can add up quickly, impacting long-term energy costs.

Three-Phase Motors

Three-phase motors, with efficiencies ranging from 85-95%, are more energy-efficient and cost-effective over time, especially in high-demand applications.

For instance, a 5 HP three-phase motor operating at 90% efficiency can handle the same workload as a single-phase motor while consuming significantly less power.

Although three-phase motors have a higher upfront cost, the long-term savings in energy and maintenance often outweigh these initial expenses in commercial and industrial settings.

To illustrate the difference, here’s a rough comparison:

- Single-Phase (1 HP at 60% efficiency): 1.6 kWh/hour at peak load

- Three-Phase (1 HP at 90% efficiency): 1.1 kWh/hour at peak load For facilities running 24/7, the cost savings on energy over time make three-phase motors the clear winner in heavy-use cases.

Energy Consumption and Cost Efficiency

Energy Efficiency and Emissions

1.Single-Phase Motors

3.Three-Phase Motors

Longevity and Maintenance

Single-Phase Motors

Single-phase motors require additional starting components like capacitors, which add to their complexity and increase maintenance needs.

The pulsating magnetic field and fluctuating torque also lead to more mechanical wear and tear, reducing the motor’s lifespan.

On average, single-phase motors might last 10-15 years in low-demand settings but require frequent servicing, particularly in higher-demand applications.

Three-Phase Motors

Three-phase motors, with their consistent rotational magnetic field, experience less vibration and mechanical stress, extending their operational life.

These motors generally require fewer maintenance interventions, often lasting 15-20 years or longer in continuous industrial use.

The combination of lower maintenance requirements and higher efficiency significantly boosts the sustainability of three-phase motors in commercial and industrial settings.

FAQ

What happens if you run a 3-phase motor on single-phase?

Running a three-phase motor on single-phase power can cause severe issues, such as reduced efficiency, overheating, and motor damage due to insufficient power for starting and continuous operation. However, using a phase converter can help simulate three-phase power, allowing the motor to operate, though typically at reduced performance.

What are the two main weaknesses of 3-phase motors?

The primary weaknesses of three-phase motors are higher initial cost and the requirement for a three-phase power supply. They are more expensive to install and require a three-phase source, which isn’t always available in residential settings. However, the benefits of efficiency and longevity often outweigh these drawbacks for industrial applications.

Can I change 3-phase to single-phase?

Yes, but it’s a complex process. While it’s possible to convert three-phase power to single-phase, the motor will typically lose efficiency and may suffer from uneven power supply. Using a phase converter or variable frequency drive (VFD) can help, but these solutions are generally more effective for adapting single-phase power to run three-phase motors.

Can 3-phase run at home?

Yes, but it depends on availability and installation costs. Three-phase power can be installed in residential settings, though it’s usually uncommon and often expensive. Residential setups are typically single-phase due to lower power demands, but homes with specific needs (like heavy machinery or commercial-grade HVAC) might benefit from three-phase power.

How much does it cost to change from single-phase to three-phase?

The cost of upgrading from single-phase to three-phase power varies widely depending on location, existing infrastructure, and distance from a three-phase power source. It can range from $1,000 to $10,000 USD or more. Costs include installing a three-phase transformer and possibly new wiring and electrical panels. Consult with local electric companies for accurate estimates.

Why is a 3-phase motor cheaper than a single-phase motor?

While the initial cost of three-phase motors is generally higher, they tend to be cheaper in the long run due to their efficiency and durability. Three-phase motors consume less power and produce less wear, reducing energy bills and maintenance costs over time. This makes them more cost-effective than single-phase motors in continuous-use settings.

How to decide whether to use single-phase or three-phase supply?

Choosing between single-phase and three-phase depends on power requirements, application type, and cost considerations. For light, intermittent loads like household appliances, single-phase is usually sufficient. For continuous, heavy-duty applications like industrial machinery, three-phase motors are ideal due to their efficiency and power output.

We offer customized motor solutions to meet your specific application requirements

LUPMOTORS offers ac low voltage 3-phase asynchronous industrial motors of all types – Please contact us freely.

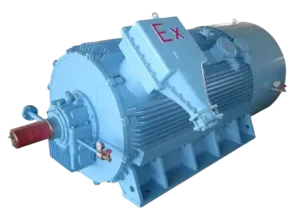

A Selection Guide for Explosion Proof Motors

Learn how to choose the right explosion-proof motor for hazardous locations. Understand classifications, T-Codes, and certifications to ensure safety and compliance!

Structure of Electric Motors | The Complete Guide

Discover the structure of electric motors, from stators and rotors to windings and bearings. Learn how materials impact efficiency, performance, and lifespan!

Motor Thermal Overload Protection | The Complete Guide

“Discover how motor thermal overload protection works, why it matters, and how to choose the right protector. Plus, take our quiz to test your knowledge!”

Brushed Motors vs. Brushless Motors: The Complete Guide

“Explore brushed vs. brushless motors: key differences, pros, cons, and which one fits your needs best!”

How to Test an Electric Motor: Tools, Methods & Procedures

Learn how to test electric motors with expert tools and methods. Discover step-by-step guides for insulation, resistance, and running current tests to ensure peak performance!

NEMA Motors vs IEC Motors: The Definitive Guide

“Explore the ultimate guide to NEMA vs. IEC motors. Learn key differences, efficiency standards, applications, and choose the right motor for industrial success.”