Industrial Three-Phase Induction AC Motors Manufacturer

Our range includes three-phase asynchronous motors with both squirrel cage and slip ring rotors, as well as direct current motors.Trust LUPMOTORS for reliable and efficient electric motor solutions.

LUPMOTORS AC Industrial Motors

LUPMOTORS Provides Industrial IEC & NEMA Standard 3-Phase asynchronous electric motors for your industrial applications.Both Low voltage electric motors & Medium and high voltage motors are for your selection.

We can customize motors according to your unique requirement.Just tell us your specific needs for the motors.

Who is LUPMOTORS?

Based in China, LUPMOTORS is a premier manufacturer and global supplier of industrial electric motors. Our range includes three-phase asynchronous motors with both squirrel cage and slip ring motors, as well as direct current motors.Trust LUPMOTORS for reliable and efficient electric motor solutions.

Three-Phase High Voltage Motors with Single/Dual Layer Sinusoidal Winding Electromagnetic Design Solutions

Designed to meet your specific applications, LUPMOTORS’ High Voltage range of motors is available in voltages from 2.3kV to 13.8kV, with options in cast iron and fabricated steel enclosures. We support all mounting forms, including Foot, Foot & Flange, Vertical Flange, and Vertical High-thrust. Our motors can be tailored for a variety of applications, including hazardous environments compliant with CSA Class 1, Division 2, ExnA, and Exp standards. They are also compatible with VFD operations and adhere to global specialty standards such as AP1541/547 and IEEE841.

IEC Three-Phase Low Voltage Motors with Single/Dual Layer Sinusoidal Winding Electromagnetic Design Solutions

Drawing from over 40 years of excellence in electric motor manufacturing, LUPMOTORS has established itself as a leader in the field, offering unparalleled domain expertise. Our three-phase induction AC motors are not only known for their reliability and high efficiency but are also tailor-made to meet the rigorous demands of diverse industry segments and applications. LUPMOTORS’ commitment to energy efficiency aids industries in minimizing their environmental footprint, aligning with contemporary ecological standards.

The right solution for Your Industrial Applications with Competitive Price

Three-phase asynchronous motors are currently the most widely used electric motors in industry. But the most common problems are the expensive price, lack of technical knowledge and not knowing the appropriate motors for your industrial applications.

International Service Line: +86 18700878815

LUPMOTORS

To Find the Best Industrial Motor Solution for You.

Motor Knowledge

A Selection Guide for Explosion Proof Motors

Learn how to choose the right explosion-proof motor for hazardous locations. Understand classifications, T-Codes, and certifications to ensure safety and compliance!

Structure of Electric Motors | The Complete Guide

Discover the structure of electric motors, from stators and rotors to windings and bearings. Learn how materials impact efficiency, performance, and lifespan!

Motor Thermal Overload Protection | The Complete Guide

“Discover how motor thermal overload protection works, why it matters, and how to choose the right protector. Plus, take our quiz to test your knowledge!”

Low voltage squirrel cage motors Series

LUPMOTORS offers compact and reliable low voltage squirrel cage motors, ideal for industrial applications like pumps, compressors, conveyors, and fans. Engineered for durability and efficiency, these motors ensure optimal performance with minimal maintenance. Choose LUPMOTORS for dependable and energy-efficient motor solutions.

Frame number range: 80-355

Power range: 0.75kW-315kW

Frequency: 50/60Hz

Number of levels: 2/4/6/8/10

Working system: S1

Protection level: IP54/IP55

Insulation class: F (Class B assessment)

Cooling method: IC411

Ambient temperature: varies with the seasons, but does not exceed 40•C.

Altitude: no more than 1000M

Voltage: 220V, 380V, 660V, 220/380V, 380/660V

Working mode: continuous (S1), allowing full pressure starting.

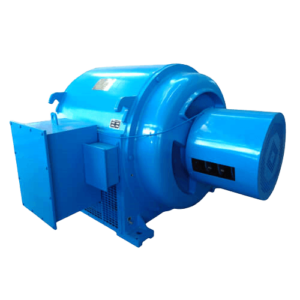

Low Voltage Slip Ring Motors

LUPMOTORS presents Low Voltage Slip Ring Motors, designed for broad industrial and shipbuilding applications. Meeting advanced drive technology needs, these motors are eco-friendly, with low noise, minimal vibration, high efficiency, and long life. Reliable in the toughest conditions, they ensure dependable, efficient operation. Choose LUPMOTORS for sustainable and powerful motor solutions.

LUPMOTORS offers Low Voltage Slip Ring Motors, perfect for applications requiring precise speed control and robust performance, such as hoists, elevators, compressors, printing presses, and large ventilating fans. These motors excel in driving lifts and pumps, showcasing their versatility across various industrial tasks. With LUPMOTORS, experience the reliability and efficiency needed for critical operations. Choose our motors for seamless integration into your demanding applications.

Frame number range: 280-315

Power range: 55-220KW

Voltage: 380V/415V/440V/660V/690V/1140V

Number of poles: 4/6/8/10/12

Rated frequency: 50Hz/60Hz

Protection level: IP44 (slip ring protection class IP23)

Cooling method: IC411

Working system: S1

Insulation class: Class F

Wiring method: stator △ connection method, rotor is Y connection method

Installation method: B3 (horizontal installation)

Ambient temperature: ≥ -15 ℃ and ≤ 40 ℃

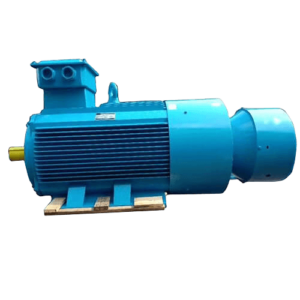

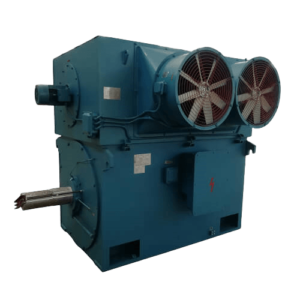

High Voltage Squirrel Cage Motors

LUPMOTORS specializes in High Voltage Squirrel Cage Motors, engineered for high-power demands with operating voltages from 2300V to 13,800V. Suitable for heavy-duty applications, these motors offer power ratings from 250HP to 10,000HP, with customization options to fit specific customer needs.

Constructed for durability, our motors thrive in tough conditions, including extreme temperatures, dust, and moisture. Featuring high-quality bearings and a precision-balanced rotor, they ensure efficient, smooth operation. Designed for convenience, they allow easy access to bearings and essential components for straightforward maintenance. Trust LUPMOTORS for reliable, high-performance motors in the most challenging environments.

Center height range: H355~1000mm

Power range: 185kW to 12000kW

Number of poles: 2/4/6/8/10/12/16

Rated voltage: 3000V/3300V/6000V/

66000V/10000V/11000V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC611/IC616

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

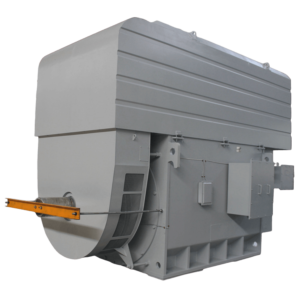

High Voltage Slip Ring Motors

LUPMOTORS presents High Voltage Slip Ring Motors, operating between 3.3kV to 13.8kV, and Medium Voltage Slip Ring Motors, designed for 690V to 3300V. These motors are built to deliver high torque and maintain exceptional performance in harsh environments. Equipped with a slip ring assembly, they offer seamless integration with external circuits, enhancing their versatility and application range.

LUPMOTORS’ High Voltage and Medium Voltage Slip Ring Motors are engineered for performance in a wide range of applications, making them a perfect choice for industries demanding reliability under challenging conditions:

Petrochemicals: Tailored to withstand the rigorous demands of the petrochemical sector, our motors excel in high temperatures, corrosive environments, and under heavy loads.

Mining: Ideal for mining operations, our motors power crushers, conveyors, and grinding mills, offering durability and efficiency even in the most demanding mining conditions.

Marine: Designed for the marine industry, our motors are utilized in propulsion systems, winches, and cranes, ensuring reliable performance in marine applications.

Center height range: H355 ~ 1000mm

Power range: 185kW ~ 5600kW

Number of poles: 2/4/6/8/10/12/16

Rated voltage: 3000V/3300V/6000V/

6600V/10000V/11000V

Rated frequency: 50HZ/60HZ

Protection level: IP54 or IP55

Insulation class: F

Work system: S1 (continuous)

Cooling method: IC611/IC616

Installation form: IMB3

Motor connection: Y (three outlet terminals in the junction box, the junction box from the extension of the spindle is located on the right side of the base)

Altitude: no more than 1000m

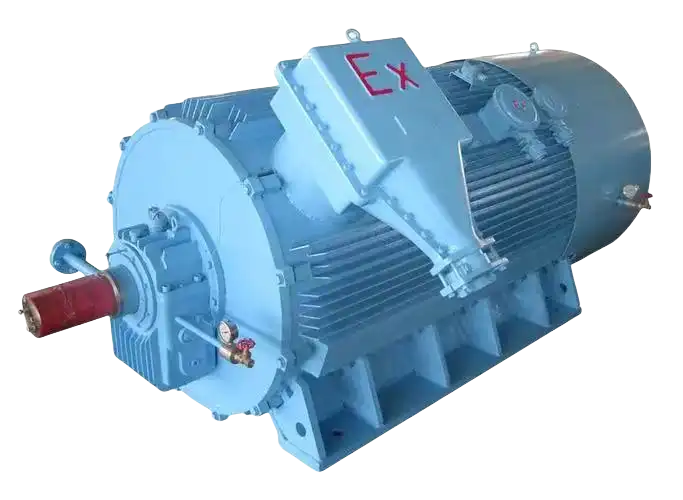

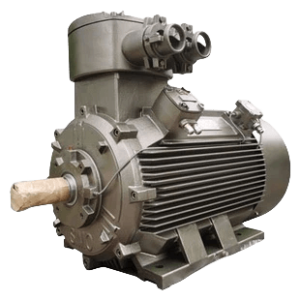

Explosion-Proof Motors

LUPMOTORS introduces the YB2 Series Asynchronous Explosion-Proof Motors, designed with advanced safety features to operate in hazardous environments. These motors come with distinct explosion-proof marks for specialized applications:

ExdI: Ideal for coal mines at risk of methane and coal dust explosions.

ExdIIBT4: Suitable for environments with Class II B explosive gas mixtures (T1, T2, T3, T4 temperature groups) commonly found in specific factory settings.

ExdIICT4: Designed for Class II Class C environments with explosive gas mixtures across T1, T2, T3, and T4 temperature groups.

Aligning with International Electrotechnical Commission (IEC) standards for power levels and installation sizes, the YB2 series also matches the German DIN42673 standard. This compatibility ensures ease of integration with both export equipment and spare parts for imported equipment, making the YB2 series a versatile choice for global applications requiring stringent explosion-proof specifications.

Motor power range is 0.55-315KW

Rated voltage: 380V, 660V, 1140V, 380/660V, 660/140V.

Rated frequency: 50Hz/60Hz.

Quota: continuous work S1

Explosion-proof signs: ExdI, ExdII AT4, Exd IIBT4, ExdIICT4.

Environmental conditions: The altitude does not exceed 1000m, and the ambient air temperature varies with the season, which is -15~40°C.

Shell protection rating: IP55.

Motor insulation class is F

Cooling method: IC411.

Installation type: B3, B5, B35, V1, etc.

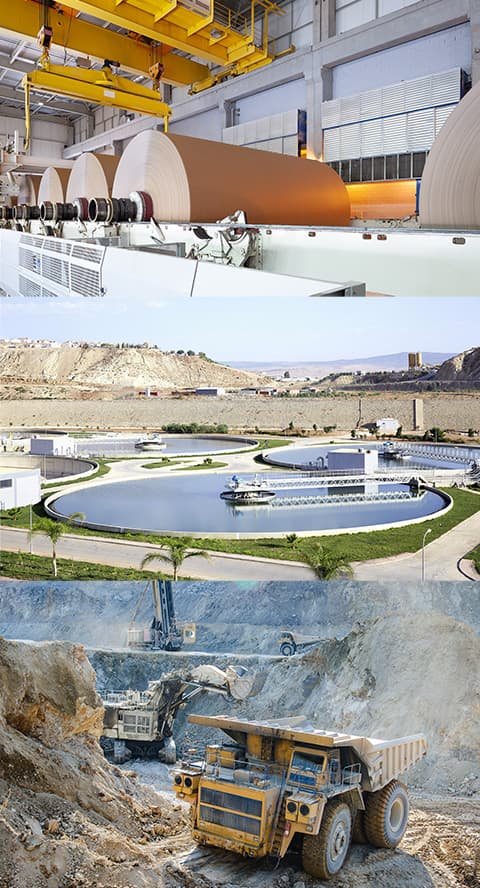

Applications

The Industrial Fan

A industrial fan is a machine that relies on input mechanical energy to increase gas pressure and discharge gas. It is a driven fluid machine.

The Water Pumps

A water pump is a machine that transports liquids or pressurizes liquids. It is mainly used to transport liquids including water, oil, acid and alkali liquids, emulsions, suspensions and liquid metals.

The Mining Machines

Mining machinery is the machinery directly used for mineral mining and mineral separation, including mining machinery and mineral separation machinery.

The Paper making Machinery

Paper making machinery refers to machinery that includes raw material preparation, pulping, paper making, and making finished rolls or flat sheets, as well as processing paper and paperboard.

The Chemical Machinery

Chemical machinery can be roughly divided into: grinding series (sand mill, colloid mill, ball mill, three-roller grinder, etc.); complete sets of coating equipment; kneading series; stirring and dispersing series; reaction series; emulsifying series; mixing series; dry powder mortar equipment; filtration series, etc.

LUPMOTORS is dedicated to ensuring the safe and efficient commissioning of high-voltage motors, offering a thorough testing and final acceptance service conducted in the customer’s presence. To achieve this, we leverage an extensive network of qualified partners, enabling us to provide expert support throughout all project phases, from planning to execution.

Our commitment extends beyond technical support; we also provide a suite of essential and beneficial documentation to aid in the commissioning process. This comprehensive service is readily available across Germany and Europe, ensuring that our clients receive the support they need, wherever they are.

At LUPMOTORS, we specialize in supplying high-voltage and medium-voltage motors that comply with both international IEC standards and American NEMA standards. Our commitment to quality is underscored by our collaboration with certified partners, ensuring that each electric motor we offer is of the highest quality.

Designed for compatibility with frequency inverters, our motors are engineered to deliver exceptional performance and reliability under varying operational conditions. Whether your application requires adherence to IEC or NEMA standards, LUPMOTORS has the expertise and the product range to meet your needs.

For detailed information about our high-voltage motors and how we can support your project with our quality-assured solutions, please don’t hesitate to contact us. Trust LUPMOTORS for your high-voltage motor requirements and experience the advantage of our globally compliant and performance-driven products.

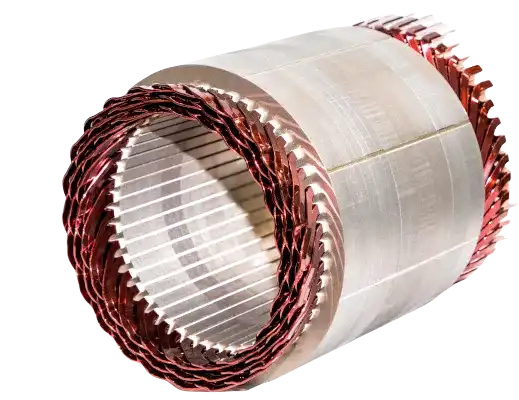

LUPMOTORS’ high and medium voltage electric motors are distinguished by their advanced construction techniques, ensuring unmatched performance and durability. Our motors feature a laminated core that is compressed, protected, and then pressed before being mounted in the frame. This meticulous process ensures exceptional insulating performance, enhanced mechanical resistance, superior humidity resistance, and extended lifespan.

Rotor Design: The rotor cage, crafted from silicon steel, can be fitted with copper bars upon request. The rotor’s fabrication involves Silicon Steel casting and subsequent welding, essential steps for maximum reliability and perfect balancing.

Bearing Options: Depending on motor power, speed, or specific customer requirements, we offer roller or bushing bearings for optimal performance.

Terminal Block Flexibility: The main terminal block is typically positioned on the motor’s right side but can be customized to the left side to meet unique installation needs. Both inside and outside the terminal box, separate terminals are provided for enhanced connectivity.

Integrated Sensors: Upon request, we can equip the stator winding and bearings with temperature-measuring sensors, promoting safe and reliable motor operation over time.

Frequency Converter Compatibility: Our high voltage electric motors can also operate with frequency converters, offering significant cost savings throughout the motor’s lifecycle.

LUPMOTORS: Customized Electric Motors with Advanced Features

LUPMOTORS specializes in custom-designed electric motors, crafted with innovative materials for optimal performance. Our motors offer a host of advantages tailored to meet the specific needs of our clients:

Extensive Customization: We provide a wide range of customization options, ensuring designs are perfectly aligned with client requirements, including any construction form.

Lightweight Design: Despite their large sizes, our motors are engineered for extreme lightness, facilitating easier handling and installation.

Maximum Efficiency: Our motors are synonymous with peak efficiency, delivering consistent performance and reliability over time.

Ease of Assembly and Maintenance: Designed with simplicity in mind, our motors ensure straightforward assembly and maintenance.

High Flexibility: Suitable for various applications, our motors offer high flexibility in use, adapting to multiple operational contexts.

Quiet Operation: Engineered for low noise and minimal vibrations, our motors provide a more comfortable and compliant working environment.

IEC Standards Compliance: All our motors meet international IEC standards, ensuring global compatibility and quality assurance.

LUPMOTORS manufactures electric motors designed for both safe environments and explosive atmospheres, catering to a wide array of industries. Our motors are essential in diverse sectors, including cement production, steel manufacturing, power generation, water purification, treatment, desalination systems, sugar processing, and wind energy generation.

Our high voltage and medium voltage motors are perfectly suited for various applications, including operation with pumps, compressors, boilers, conveyor belts, fans, blowers, mills, crushers, shredders, laminators, and steel plant equipment. They are also ideal for turbines and all types of heavy industry machinery.

LUPMOTORS offers these motors with either a squirrel-cage rotor or a wound rotor, providing flexible solutions tailored to meet specific operational needs. Our commitment to quality and versatility ensures that LUPMOTORS motors deliver reliability and performance across all applications. Trust LUPMOTORS for electric motor solutions that drive productivity and safety in any industrial setting.

Get Answers to Your Questions

Reach out to our team at the LUPMOTORS China headquarters for any inquiries or support you need regarding our high-voltage motor solutions. We are committed to providing prompt and efficient responses to ensure your needs are met swiftly. Trust in LUPMOTORS for unparalleled service and expertise. We look forward to assisting you and will reply at the earliest opportunity.