Electric motors are used in every industry, from manufacturing to agriculture and even everyday appliances.

But do you really know how to calculate the RPM of a motor?

If you don’t get the knowledge of it, it’s possible to choose the wrong motor for your needs, which will lead to problems like overheating, energy waste, or equipment failure.

That’s why I want to write this article.

By the end of this post, you’ll learn how to calculate motor RPM for both AC and DC motors, ensuring you choose the right one for your need.

1.Basics of Motor Speed

1.1 What is Motor RPM?

RPM is the abbreviation of “Revolutions Per Minute.”

It means how many times a motor’s shaft completes a full rotation in one minute,which shows how fast the motor rotates.

RPM helps us know how much power or speed a motor can deliver to connected machines or tools.

1.2 Why Should you Know the RPM Knowledge?

Accurate RPM knowledge ensures you make the right choices when selecting or maintaining motors, saving both time and money in the long run.

The RPM will affect:

- Efficiency: A motor operating at the correct RPM consumes less energy and runs smoothly. This means lower energy costs and fewer overheating.

- Equipment Compatibility: Motors need to match the requirements of the devices. If the RPM is wrong, it can reduce the lifespan of both the motor and equipment.

- Energy Usage: Motors which operate at right RPM levels will use less energy.

2.Types of Motors and Their RPM Calculation

2.1 AC Motors vs. DC Motors

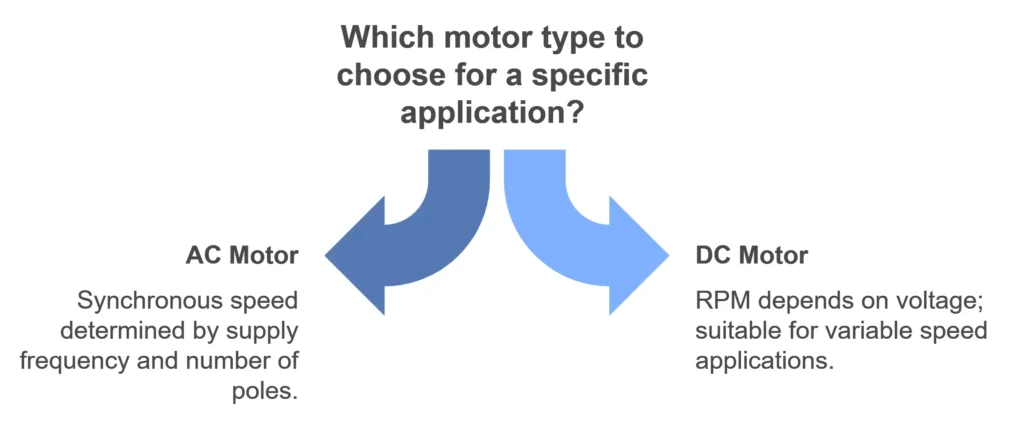

- AC Motors: The speed of an AC motor is determined by its synchronous speed, which depends on the frequency of the electrical supply and the number of poles in the motor.

- DC Motors: Unlike AC motors, the RPM of a DC motor depends on the voltage applied to it. The more voltage supplied, the faster the motor rotates. We can adjust the the RPM of the DC motors by change the voltage. This is why the DC motors are often used in applications which need variable speeds, such as in electric vehicles and conveyor systems.

Understanding these differences helps you select the right type of motor for your needs and calculate their RPM accurately.

3.How to Calculate RPM for AC Motors

There are 3 formulas which we need to learn.

- No-load RPM

- RPM Slip

- Full-load RPM

3.1 No-load RPM

The no-load speed means the motor’s speed without any external load applied.

To calculate the No-load RPM, you need to use the synchronous speed formula,which is:

$$ \text{Synchronous RPM} = \frac{\text{Frequency (Hz)} \times 60 \times 2}{\text{Number of Poles}} $$

Explanation:

- Frequency (Hz): This is the electrical frequency of the power supply. In many regions, it’s typically 50 Hz or 60 Hz.

- 60: Means the number of seconds in a minute, converting frequency to RPM.

- 2: Means the full rotation per cycle.

- Number of Poles: Means the number of magnetic poles in the motor. More poles generally mean a lower RPM.

For example, if you have a 4-pole AC motor and the frequency is 60 Hz, the calculation would be:

$$ \text{Synchronous RPM} = \frac{60 \times 60 \times 2}{4} = 1{,}800 $$

You can use this Motor RPM calculator to get the result.

RPM Calculator

Speed (RPM): –

3.2 RPM Slip

In our daily working circumstances, AC motors don’t run at the synchronous speed.

There’s a difference called “slip,” which is essential for the motor to make torques.

Slip is the percentage difference between the synchronous RPM and the actual RPM under load.

How to Calculate RPM Slip:

$\text{RPM Slip} (\%) = \frac{\text{Synchronous RPM} – \text{Actual RPM}}{\text{Synchronous RPM}} \times 100\%$

RPM slip let the motor make torques.It is from 2% to 5%.

3.3 Full-load RPM

To calculate the full-load RPM, you need to account for RPM slip. Use the following formula:

Full Load RPM=Synchronous RPM -(Synchronous RPM × Slip Percentage)

For example, if the synchronous RPM is 1,800 and the slip RPM is 3%, the calculation should be:

Full Load RPM=1,800-(1800×0.03)=1,746RPM

This provides an authentic figure for the motor’s speed under operating conditions.

3.4 Example Calculation

Let’s go to a complete example to make it clear:

1.No-load RPM: For a 60 Hz, 4-pole motor, the synchronous speed is:

$$ \text{Synchronous RPM} = \frac{60 \times 60 \times 2}{4} = 1{,}800 \ \text{RPM} $$

2.Slip Calculation: Suppose the slip is 3%.

$$ \text{Slip} (\%) = 3\% $$

3.Full-load RPM(Actual RPM):

Full Load RPM=1,800-(1800×0.03)=1,746RPM

By understanding these calculations, you can accurately determine how fast an AC motor will run under different conditions. So you can select the right motor for your equipment.

4.How to Calculate RPM for DC Motors

4.1 Relationship Between Voltage and Speed

For DC motors, there’s a relationship between the voltage and the motor’s speed (RPM).

The speed of a DC motor is related to the applied voltage.

If you increase the voltage, the motor rotates faster. If you decrease the voltage, and the motor will slow down.

The formula is:

$$ \text{RPM} \propto \text{Voltage} $$

This means if you double the voltage, the RPM will roughly double as well.

However, keep in mind that this linear relationship holds true under normal operating conditions and without any significant load affecting the motor’s performance.

For precise speed control, devices like Pulse Width Modulation (PWM) are often used to adjust the effective voltage supplied to the motor.

4.2 Example Calculation

If you have a DC motor that runs at 1,200 RPM when it is supplied with 12V. If you want to find out the RPM when you increase the voltage to 24V, you can use the following formula:

$$ \text{New RPM} = \text{Original RPM} \times \frac{\text{New Voltage}}{\text{Original Voltage}} $$

Given:

- Original RPM = 1,200 RPM

- Original Voltage = 12V

- New Voltage = 24V

$$ \text{New RPM} = 1{,}200 \times \frac{24}{12} = 1{,}200 \times 2 = 2{,}400 $$

So, by doubling the voltage, the motor speed also doubles to 2,400 RPM.

This calculation makes it easy to show you how voltage change will impact the motor’s performance. So we can do some speed adjustments for DC motors when we need.

5. Visual Guide: Motor RPM Calculation Chart

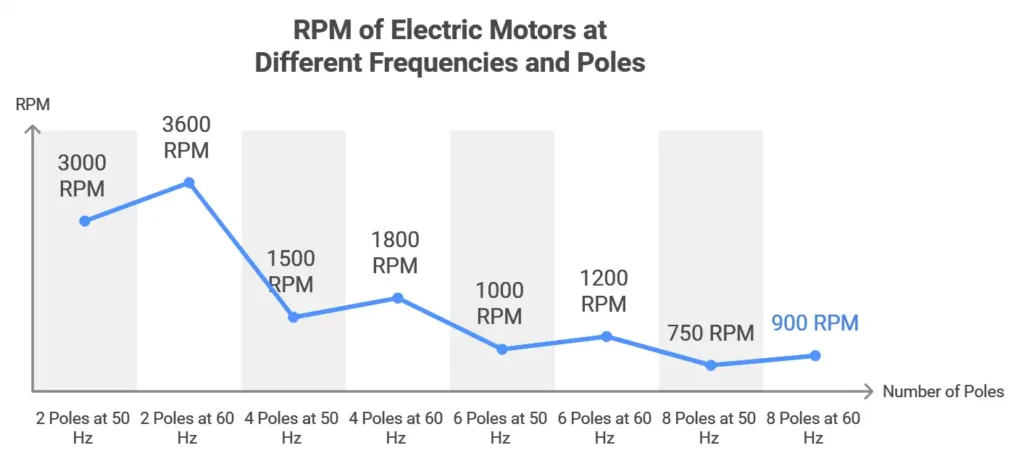

5.1 Motor Speed Chart

This table helps you quickly determine the synchronous speed of a motor based on the standard power supply frequencies and pole configurations.

| Poles | 50 Hz (RPM) | 60 Hz (RPM) |

| 2 | 3000 | 3600 |

| 4 | 1500 | 1800 |

| 6 | 1000 | 1200 |

| 8 | 750 | 900 |

5.2 Diagram Explanation

To better understand how motor speed varies, imagine a visual diagram where:

- The horizontal axis represents the frequency (in Hz).

- The vertical axis shows RPM.

- Lines represent different pole configurations (2, 4, 6, 8 poles).

When the frequency increases, the RPM rises, and motors with fewer poles run faster than those with more poles.

This relationship helps in choosing the right motor type for specific speed requirements, especially in applications where precise RPM control is necessary.

6. FAQs About Motor RPM

Q1: What is the RPM of an electric motor?

The RPM (Revolutions Per Minute) of an electric motor is a measure of how many times the motor’s shaft completes a full rotation in one minute. It varies based on the motor type, number of poles, and the frequency of the power supply. For example, a typical 4-pole AC motor running on a 60 Hz supply will have a synchronous speed of 1,800 RPM.

Q2: How do you calculate 3-phase motor current?

To calculate the current for a 3-phase motor, you can use the formula:

$$ \text{Current (I)} = \frac{\text{Power (P)}}{\sqrt{3} \times \text{Voltage (V)} \times \text{Power Factor (PF)}} $$

where:

Power (P) is the output power of the motor in watts.

Voltage (V) is the line voltage.

Power Factor (PF) indicates how effectively the motor uses electricity (typically between 0.7 and 0.9).

Q3: Can motor speed be adjusted after installation?

Yes, motor speed can be adjusted even after installation, especially in AC motors using a Variable Frequency Drive (VFD). A VFD changes the frequency of the power supply, which directly alters the RPM. For DC motors, speed can be adjusted by varying the voltage supplied. This flexibility makes it easier to optimize motor performance for different tasks, leading to energy savings and better control.

Data References

1.Revolutions per minute Wikipedia https://en.wikipedia.org

2.Electric motor Wikipedia https://en.wikipedia.org