IEC Low Voltage industrial electric AC Motors wholesale

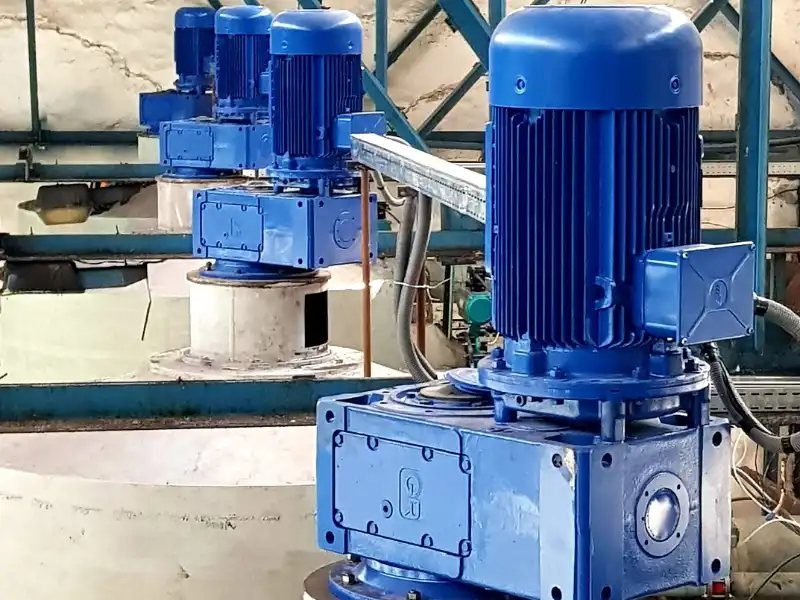

LUPMOTORS is a famous manufacturer and agency of 3-phase AC motors in China. We wholesale electric motors over 40 years.Explore how our custom-designed IEC three-phase induction AC electric motors, built to meet your specific requirements, can elevate your production efficiency. Experience exceptional performance and enhanced durability with our motors, engineered precisely for your unique industrial applications. Enhance your operational outcomes today. Reach out to us to upgrade your plant!

Low Voltage IEC electric industrial Motors

Drawing from over 40 years of excellence in IEC electric motor manufacturing and wholesaling, LUPMOTORS has established itself as a leader in the field, offering unparalleled domain expertise. Our three-phase electric motors are not only known for their reliability and high efficiency but are also tailor-made to meet the rigorous demands of diverse industry segments and applications. LUPMOTORS’ commitment to energy efficiency aids industries in minimizing their environmental footprint, aligning with contemporary ecological standards.

Our extensive support network ensures easy maintenance throughout the product’s lifespan, empowering customers like Marranie in Brazil and others globally to optimize their total cost of ownership. With proven design and rigorous testing, LUPMOTORS guarantees safe operation even in the most challenging environments. Our focus on innovation, quality, and customer service makes us a trusted partner for businesses looking to advance their operations with superior electric industrial motor solutions.

Motor Selection Tool

Custom-Engineered Three-Phase AC Low Voltage IEC Standard motors for Your Unique Applications

At LUPMOTORS, we recognize the distinct requirements of your projects and tailor our IEC standard three-phase electric AC motors accordingly. We are more than just a manufacturer; we are your partner in efficiency, providing motors designed to meet the exact specifications of your industrial applications. Here’s how we ensure our solutions align with your unique needs:

Customized Solutions: Your project’s requirements are distinct, and our approach to customization reflects this. We adapt the size, shape, and configuration of our three-phase electric industrial motors to meet your exact needs, ensuring a perfect fit for your applications.

Diverse Motor Options:Our electric industrial motors are available with adjustable voltage and frequency settings, providing the flexibility to select the ideal specifications for your application’s needs, thereby optimizing both performance and longevity.

Optimized Performance:Our motors are available with adjustable voltage and frequency settings, providing the flexibility to select the ideal specifications for your application’s needs, thereby optimizing both performance and longevity.

Precision Engineering:Tailor the operational parameters of our IEC electric industrial motors to achieve the specific performance characteristics required for your applications, ensuring superior results.

At LUPMOTORS, we are committed to delivering three-phase induction AC motors that not only meet but exceed the specific needs of your projects. Our dedication to flexibility and customization guarantees you receive motors that are perfectly aligned with your business requirements. Connect with us to enhance your operations with the precision and quality of our custom-engineered motors.

More Than Just a Leading 3-Phase electric industrial motors Manufacturer

At LUPMOTORS, Our Commitment to Timely Support, Upholding High IEC & ISO Standards, and Delivering Tailored Solutions Drives Our Reputation.

IEC Motor Recommendation

If you’re unsure about which three-phase induction motor best suits your project or industrial machines, rely on LUPMOTORS to suggest options that align with your requirements and intended application.

24-hour Expert Technical Support

Should you have queries regarding our 3-phase electric industrial motors, feel free to reach out. We’re dedicated to offering assistance and can even dispatch an engineer to your project site for hands-on support.

Wide range Mortor Grades you can select

If you’re NOT sure which motor efficiency class—IE2, IE3, IE4, IE5, YE2, YE3, YE4, or YE5— are the best grade for your project, rely on LUPMOTORS to suggest options that align with your requirements and intended application.

Precision Fabrication and inspection of the industrial IEC Motors

With over a decade of experience in the titanium industry, you can trust us to machine and finish your titanium mesh with precision, adhering to your exact specifications.

Get 2% Discount Coupon for Our IEC Motors If You Contact Us Today.

Provide more considerate IEC Motor Solutions for Your Industry

Aluminum or Cast Iron Frame 3-Phase AC Low Voltage Electric Motor, How to Select?

Aluminum Frame 3-Phase AC Motors

Aluminum shell AC electric motors: It is made of high-quality aluminum material. The advantage of this material is its lightweight design, which can significantly improve the heat dissipation performance and the heat conduction effect is also very good. Aluminum also has good plasticity and die-casting capabilities, and is more ductile than iron, so it makes less noise during operation and runs more smoothly.

Of course, the cost of aluminum-shell motors will be relatively high and their hardness is slightly lower, so they are more suitable for scenarios that do not require excessive loads. Since aluminum is less dense, this also helps reduce the weight of the overall device. For small-sized motors, we give priority to aluminum shells while ensuring strength, because they not only have superior performance, but also have a more beautiful appearance and are very cost-effective.

When choosing a small motor, we give priority to using an aluminum shell, mainly based on the following reasons:

First, aluminum has a low density, which can effectively reduce the weight of the entire motor, which is very beneficial in many applications. Second, aluminum has excellent thermal conductivity, which is more conducive to the heat dissipation of the motor than iron, ensuring that the motor maintains a stable temperature during operation. In addition, due to the relatively low strength of aluminum, it is easier to process and manufacture, thereby reducing processing costs.

It should be noted that in AC motors, the housing does not participate in the conduction of the circuit and magnetic circuit, so it has no direct impact on the electrical performance of the motor, and mainly plays a role in the mechanical performance. Therefore, choosing an aluminum shell can provide a lighter and more economical solution while ensuring performance.

Aluminum housing 3-phase IEC industrial motors are widely used in the following fields:

- wastewater treatment plants

- Food and beverage manufacturing

- Conveying systems

- HVAC systems

- Refrigeration equipment

Cast Iron Frame 3-Phase AC Motors

Cast iron electric motors: The housing is made of durable cast iron. The advantages of this material are its high hardness, ability to withstand large external pressure, not easy to deform, and relatively low price. It is very suitable for use in places where high-power drive is required and the working environment is relatively harsh.

Of course, cast iron motors also have some disadvantages, such as heavy weight, relatively poor thermal conductivity, and cannot be die-cast, and the shaping ability is also weak. In addition, cast iron is not as ductile as aluminum, it is relatively noisy during operation, and its stability is slightly inferior to that of aluminum shell motors. Iron shell motors are prone to rust in humid environments, and although aluminum shell motors have poor corrosion resistance, their heat dissipation performance is far better than cast iron. Therefore, when choosing, it is necessary to weigh the specific use environment and needs.

The difference between the motor aluminum shell and the cast iron shell. Is the motor shell cast iron or aluminum?

Motors with shaft heights above 315 almost have no aluminum shells because of poor mechanical strength. Motors with shaft heights of about 80 to 225 have both cast iron shells and aluminum shells. These two materials should not have a big impact on the overall performance of the motor.

Cast iron three-phase IEC industrial motors are commonly used in the following applications:

- Extruders

- Heavy industry

- Scrap metal processing plants

- High-power water pumps

- Large industrial fans

Comparison of aluminum and cast iron AC electric industrial motors

This table will illustrate the differences between the aluminum frame motor and the aluminum frame IEC motors.

| Aluminum Frame Three-Phase Motors | Cast Iron Frame Three-Phase Motors | |

|---|---|---|

| Rated Power | 0.75kW - 37kW | 0.75kW - 315kW |

| Frame Sizes | 80 - 200 | 80 - 355 |

| Anti-corrosion | √ | × |

| IE2 Available | √ | √ |

| IE3 Available | × | √ |

| Frequency | 50 / 60 Hz | 50 / 60 Hz |

Provide more considerate IEC Low Voltage electric motor solutions for your industry

Consult your motor expert

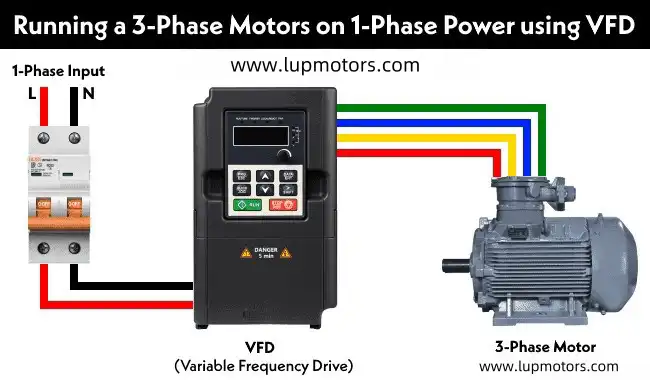

Can I use a three phase electric motor with a variable frequency drive?

Yes, you can. All our electric industrial motors are compatible with frequency converters, and the relevant adaptation parameters are clearly marked on the nameplate on the side of the motor. In this way, you can safely use our motors with frequency converters to ensure that the system can operate efficiently and stably under different working conditions.

Prolonged Low-Speed Operation with an Inverter?

When operating your three-phase electric industrial motors at low speeds for extended periods using an inverter, it’s crucial to ensure proper cooling. The standard fan, which is directly driven by the motor’s rotor, may not provide enough airflow when the motor runs at low speeds. The lack of airflow can lead to overheating, especially under heavy loads.

To prevent this, consider installing a Forced Ventilation Unit. Unlike the standard fan, the Forced Ventilation Unit operates independently of the motor speed, ensuring consistent and sufficient airflow to cool the motor effectively, regardless of its operating speed. This additional cooling solution is essential for maintaining the motor’s performance during prolonged low-speed operations.

What is the Determination of Speed of Your Electric Motor?

The speed of a 3-phase induction AC motor is determined by the number of poles it has.

In simple terms, the fewer the poles, the higher the motor’s base speed (maximum RPM).

Conversely, as the number of poles increases, the motor’s speed decreases, but it gains more torque, making it more powerful for heavy-duty applications.

Motor synchronous speed = 60*power frequency/pole number.

The formula is n=60f/p, where f is the power frequency, p is the pole number, and n is the motor synchronous speed.

If f=50HZ, the speed of a pair of rotating magnetic fields is 50r/min×60 r/min =3000 r/min.

| Pole Number | |

|---|---|

| 2 poles | 3000rpm |

| 4 Pole | 1500rpm |

| 6 Pole | 1000rpm |

| 8 Pole | 750rpm |

Provide more considerate IEC indusrtial electric motor solutions for your industry

Consult your motor expert

REQUEST A QUOTE FOR MORE DETAILS

Your Comprehensive Guide to Selecting AC Three-Phase electric Motors--What is a Three Phase Induction Motor?

Many people struggle to understand how a three-phase electric industrial motor works.

This confusion often leads to costly mistakes and inefficiencies in industrial settings.

Let’s break down the basics of the three-phase induction motor, a crucial component in many industries, and help you avoid these common pitfalls.

All You Need To Know About the Low Voltage AC Electric Motors

CHAPTER ONE

Introduction of three phase electric motors

The three-phase asynchronous industrial motor is a type of electric motor that is powered by a three-phase AC power supply.

Since the rotor and the rotating magnetic field of the stator of the three-phase asynchronous electric motor rotate in the same direction but at different speeds, there is a slip rate, so it is called a three-phase asynchronous electric motor.

The speed of the rotor of the three-phase asynchronous motor is lower than the speed of the rotating magnetic field.

The rotor winding generates electromotive force and current due to the relative motion between the rotor and the magnetic field, and interacts with the magnetic field to generate electromagnetic torque to achieve energy conversion.

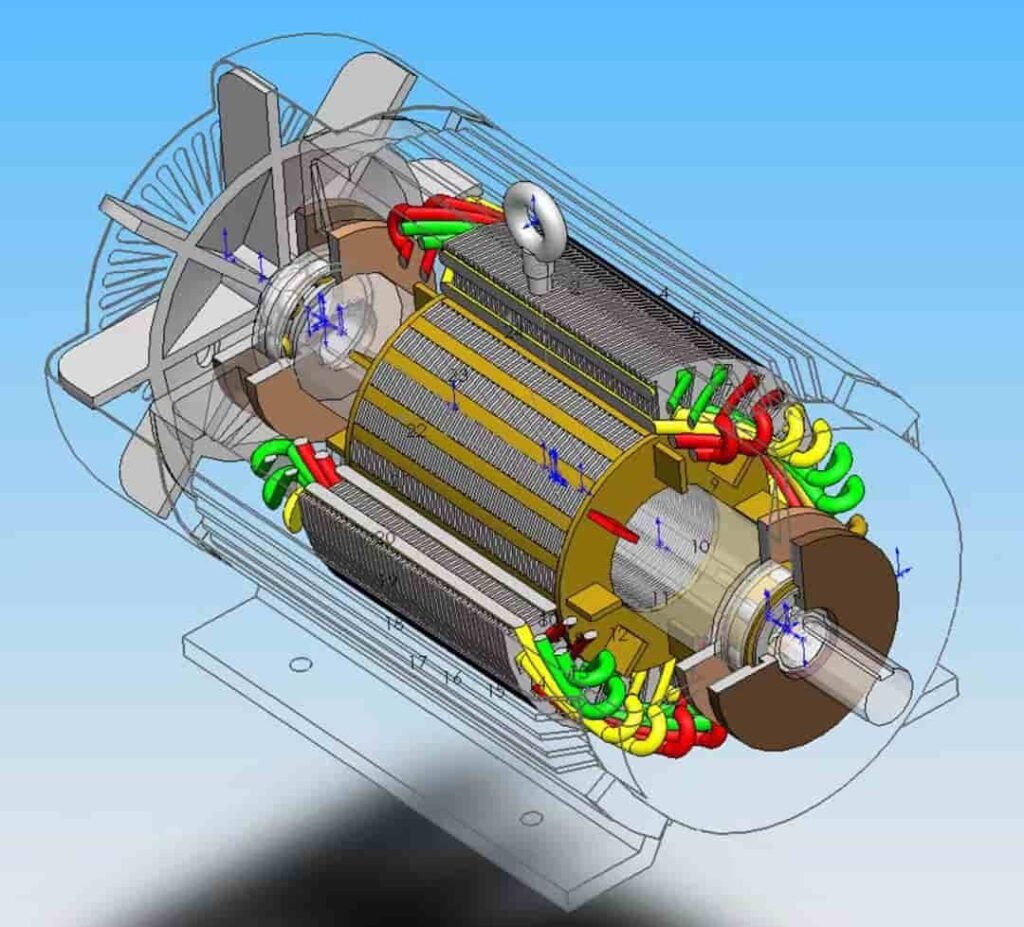

CHAPTER TWO

Components and Construction for three phase electric motors

1.Detailed description of the stator

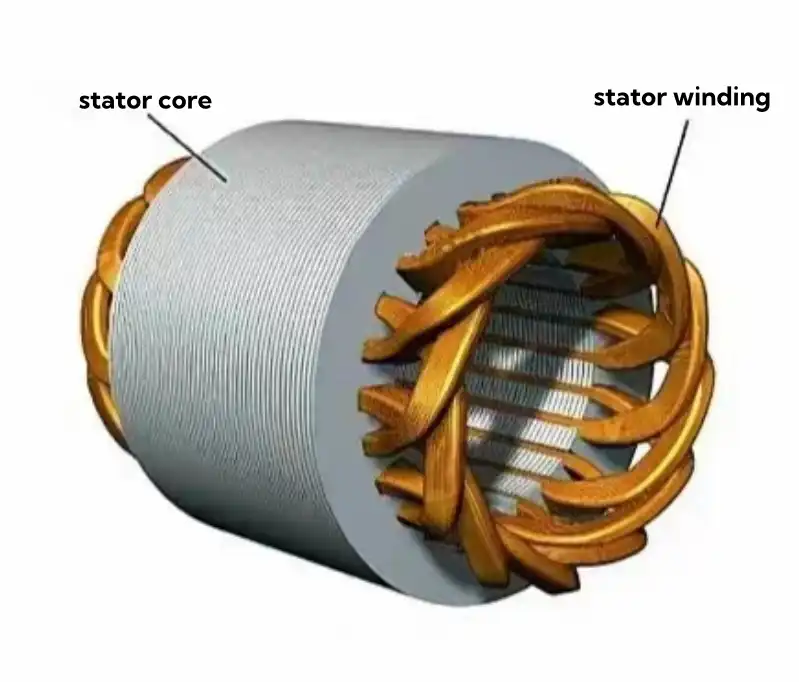

The stator consists of three parts: the base, the stator core and the stator winding.

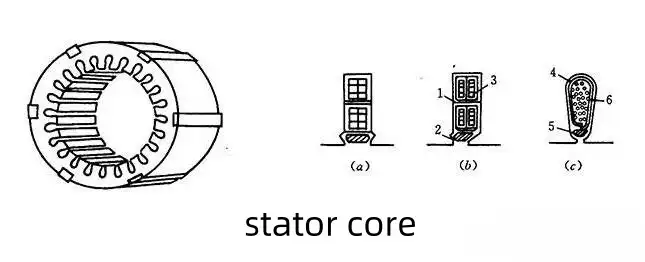

1.1 Stator core

The stator core is part of the motor magnetic circuit and is installed in the base.

In order to reduce the iron loss in the stator core, the stator core is made of laminated silicon steel sheets, and insulating paint should be applied on both sides of the silicon steel sheets.

The following figure shows the stator slots, where (a) is an open slot, which is used in large and medium-sized high-voltage asynchronous motors; (b) is a semi-open slot, which is used in medium-sized asynchronous motors below 500V; (c) is a semi-closed slot, which is used in low-voltage small asynchronous motors.

1.2 Windings

The stator winding is wound with insulated copper wires and embedded in the stator slots.

1.3 The base

The motor base is used for fixing and supporting.

Each motor has its own frame size , which indicates the height of the motor shaft center from the horizontal base, expressed in millimeters.

For example, If the frame size of a motor is 200, which means the height from base of foot to centre of shaft= 200mm.

2.Detailed description of the rotor

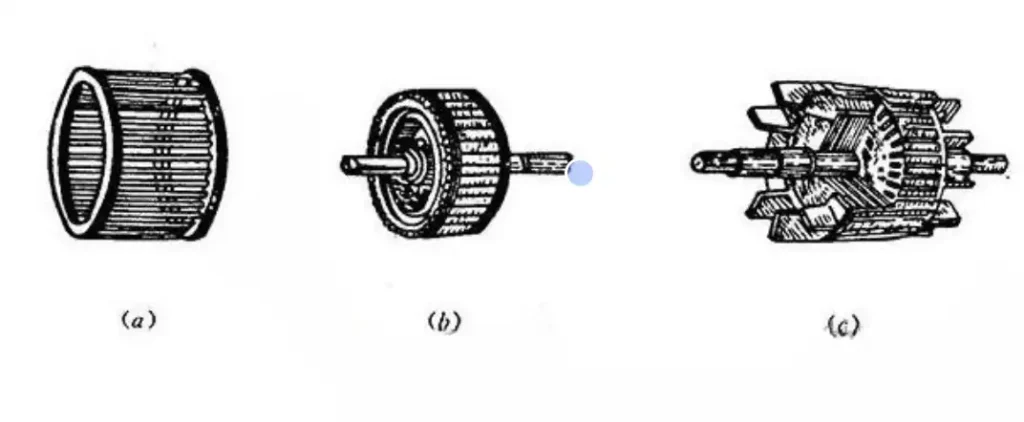

The rotor consists of a rotor core, rotor windings and a rotating shaft.

The rotor core is part of the motor magnetic circuit and is made of laminated silicon steel sheets. The core is fixed on the rotating shaft or rotor bracket, and the entire rotor has a cylindrical appearance.

The rotor windings are divided into two types: cage type and winding type.

2.1 Squirrel cage rotor

The cage winding is a self-short-circuited winding.

A conductor is placed in each slot of the rotor, and the two ends of the core are connected with end rings to form a short-circuited winding.

If the rotor core is removed, it can be seen that the remaining winding is shaped like a squirrel cage, as shown in Figure (a), so it is also called a squirrel cage rotor.

The conductor bar can be made of copper or aluminum.

If copper is used, it is necessary to insert the pre-made bare copper bars into the slots on the rotor core, and then use copper end rings to cover the copper bars at both ends, and finally weld them together, as shown in Figure (b).

If cast aluminum is used, it is cast together with the end rings and fan at one time, as shown in Figure (c).

The cage rotor has a simple structure, is easy to manufacture, and is an economical and durable motor, so it is widely used.

2.2 Wound rotor

The slots of the wound rotor are embedded with three-phase windings composed of insulated wires, which are generally connected in a Y shape.

The three leads of the rotor winding are connected to three slip rings respectively and led out with a set of brush devices, as shown in the figure.

This allows the external resistor to be connected in series to the rotor winding circuit to improve the starting performance of the motor or adjust the speed of the motor.

2.3 Comparison of differences between the Squirrel cage rotor and the wound rotor the wound rotor

2.3.1 the wound rotor

- 1.low starting current

- 2.complicated structure

- 3.high maintenance costs

- 4.small starting current situations

- 5.Cost more

- 6.Low power factor

2.3.2 The squirrel cage rotor

- 1.Large starting current

- 2.Simple structure

- 3.Low maintenance cost

- 4.Cost effectively

- 5.Low torque starting

Provide more considerate motor solutions for your industry

Consult your motor expert

CHAPTER THREE

Working Principle of the three phase induction motors

1. Explanation of how a three-phase motor works

The working principle of the three-phase AC asynchronous motor is that it uses the interaction between the rotating magnetic field generated by the three-phase power supply and the rotor induced electromotive force.

This interaction allows the motor to generate sufficient torque to drive the mechanical equipment to operate normally.

Specifically, the three-phase current of the three-phase power supply passes through the three-phase coils of the motor in sequence to form a rotating magnetic field.

The interaction between this rotating magnetic field and the rotor induced electromotive force is the working basis of the three-phase asynchronous motor.

When the rotor induced electromotive force interacts with the rotating magnetic field, torque is generated to make the motor rotate.

2. Electromagnetic induction and rotating magnetic field

(1) When a three-phase asynchronous motor is connected to a three-phase AC power supply, a three-phase symmetrical current flows through the three-phase stator winding to generate a three-phase magnetomotive force (stator rotating magnetomotive force) and generate a rotating magnetic field.

(2) The rotating magnetic field has a relative cutting motion with the rotor conductor.

According to the principle of electromagnetic induction, the rotor conductor generates an induced electromotive force and an induced current.

3. Interaction between stator and rotor

According to the law of electromagnetic force, the rotor conductor carrying current is acted upon by electromagnetic force in the magnetic field, forming an electromagnetic torque, driving the rotor to rotate.

When the motor shaft carries a mechanical load, mechanical energy is output to the outside.

Provide more considerate AC motor solutions for your industry

Consult your motor expert

CHAPTER FOUR

Operation Mechanism of AC Three Phase Electric Motors

1. Explanation of synchronous speed and poles

In daily work, for a three-phase asynchronous motor, you may often ask, how many poles does this motor have? For example, 2 poles, 4 poles, 6 poles, 8 poles… Then you can judge its rated speed by its number of poles.

So what is the relationship between the number of poles and the speed of the motor?

The number of poles of the motor refers to the number of magnetic poles uniformly distributed in the stator circumference of each phase coil. The magnetic poles appear in pairs, N poles and S poles, so the number of poles of a motor is at least 2 poles. The more poles, the lower the speed, the fewer poles, the higher the speed.

The relationship between the speed and the number of poles can be calculated by the formula: n=60f/p.

n: speed.

60: 60 seconds, the speed of this motor we usually say refers to the number of revolutions per minute of this motor, that is, the number of revolutions in 60 seconds.

f: grid frequency, my country is 50HZ.

p: number of motor pole pairs, 2-pole motor, the number of pairs is 1; 4-pole motor, the number of pairs is 2; 8-pole motor, the number of pairs is 4.

For example, for a 2-pole motor, the speed n=60 seconds×50HZ/pole pair number 1=3000 rpm. But this is the synchronous speed.

For an asynchronous motor, the rotor speed is lower than the stator rotating magnetic field speed.

Therefore, the asynchronous speed also involves the motor slip factor.

The slip rate = (stator speed-rotor speed)/stator speed.

The motor slip rates of different manufacturers are also different, usually within 10%, generally around 4%.

The relationship between asynchronous speed and slip rate: N=(60F/P)×(1-S%), so the asynchronous speed of a 2-pole motor = 3000×(1-4%) = about 2880 rpm.

Using the same algorithm, the asynchronous speed of a 6-pole motor = (60 seconds×50 Hz/pole pair number 3)×(1-slip rate 4%) = about 960 rpm.

Provide more considerate motor solutions for your industry

Consult your motor expert

CHAPTER FIVE

Types of Three Phase Induction Motors

1. Squirrel Cage Induction Motor

1.1Construction and features

The rotor winding of the squirrel cage type three-phase asynchronous motor is a self-short-circuited winding.

A conductor is placed in each slot of the rotor.

The conductor is longer than the iron core. Two end rings are used to short-circuit the conductor at both ends of the iron core to form a short-circuit winding.

If the iron core is removed, the remaining winding is shaped like a squirrel cage, so it is called a squirrel cage winding.

Advantages: simple structure, easy to start, reliable operation, small size, durable, easy to maintain, repair and install, low cost, etc.

Disadvantages: small starting torque, low power factor, difficult to adjust the speed, large starting current when starting directly. Under normal circumstances, the squirrel cage motor is started 2-3 times in cold state, and the interval time each time shall not be less than 5 minutes. It is started once in hot state. When squirrel cage asynchronous motor is started frequently, it is easy to cause the cage to break.

1.2 Applications

Daily life, factory equipment, port terminals, oil fields and coal mines

2. Wound Rotor Induction Motor

2.1 Construction and features

Three-phase wound rotor AC asynchronous motor (also known as slip ring motor).

It is necessary to install a resistor or reactor in the rotor circuit of the motor to reduce the starting current, so that it has a higher power factor and a larger starting torque during starting, thereby effectively improving the starting performance of the motor.

Advantages: By inserting an external resistor in series in the rotor circuit, the starting current and speed are reduced, and the starting torque is increased. The starting and speed regulation performance of the motor can be improved.

Disadvantages: Complex structure, troublesome maintenance, poor operating reliability, and expensive

2.2 Applications

Driving equipment in metallurgy, machinery, chemical industry, mining, building materials and other fields

3. Differences between the Wound Rotor Induction Motor and the Squirrel cage motors

Squirrel cage and wound-rotor three-phase asynchronous motors refer to three-phase asynchronous motors whose rotors are wound-rotor or squirrel cage.

Their starting methods are slightly different.

First, they can both be started directly.

Secondly, because of the structure of the rotor, the squirrel cage asynchronous motor must use external equipment (autotransformer or contactor) to achieve reduced voltage starting.

In addition to using external equipment to achieve reduced voltage starting, the wound-rotor asynchronous motor also relies on adjusting the rotor current to achieve reduced voltage starting (with an adjusting resistor in series on the rotor return).

The difference in operation is also the same, and the rest is the same.

Provide more considerate IEC motor solutions for your industry

Consult your motor expert

CONTACT US

Connect for Industrial AC Motor Solutions

We invite you to connect with us today to explore the extensive range of possibilities our IEC Motors and services offer. Whether you’re looking to optimize efficiency, reduce operational costs, or integrate advanced automation into your processes, our team is equipped to guide you through every step of commissioning our solutions for your application.

- Tel: +86 029 87809520

- Mobile: +86 18700878815

- sam@lupmotors.com