Product Ranges

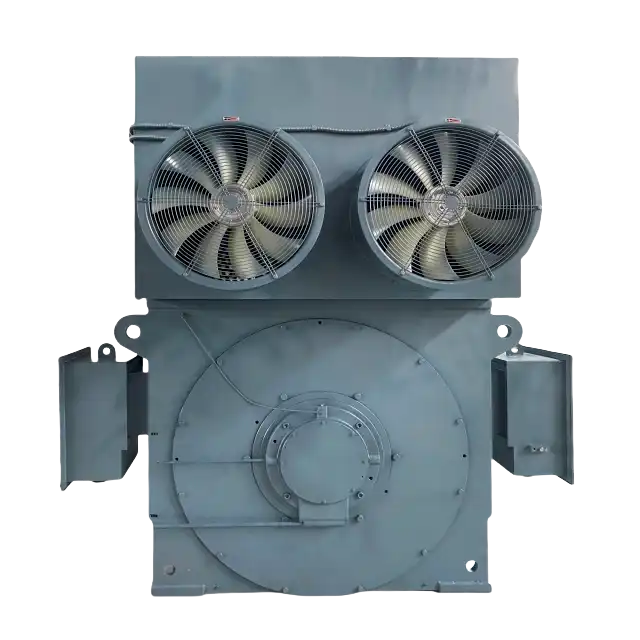

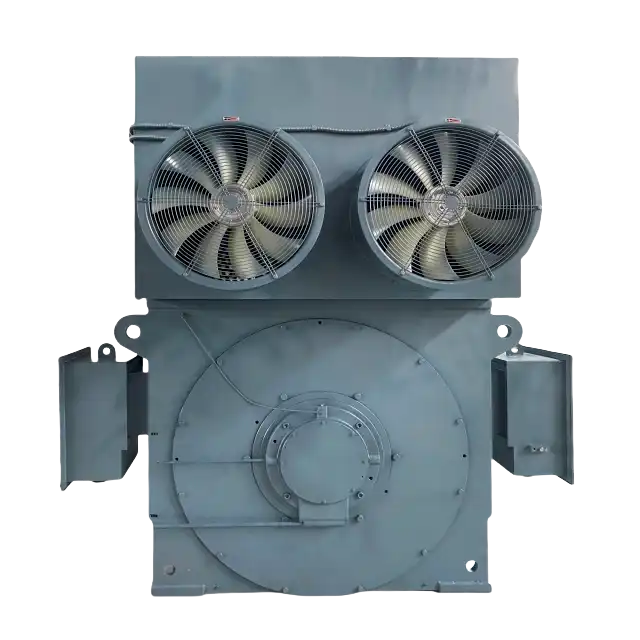

TEAAC IC666 High Voltage Variable Frequency AC Induction Motor

TEAAC IC666 series motors are new speed-regulating motors independently developed by LUPMOTORS based on market demand. They use variable frequency speed regulating devices as power supply. The power level, electrical performance and installation dimensions of the motors are in compliance with the IEC standards of the International Electrotechnical Commission. This series of motors can be continuously regulated within the range of 5-67Hz, i.e., 5-50Hz for constant torque operation and 50-67Hz for constant power operation.

This series of motors generally have the advantages of high efficiency and energy saving, low noise, low vibration, wide speed regulation range, high precision and reliable quality, easy installation, use and maintenance.

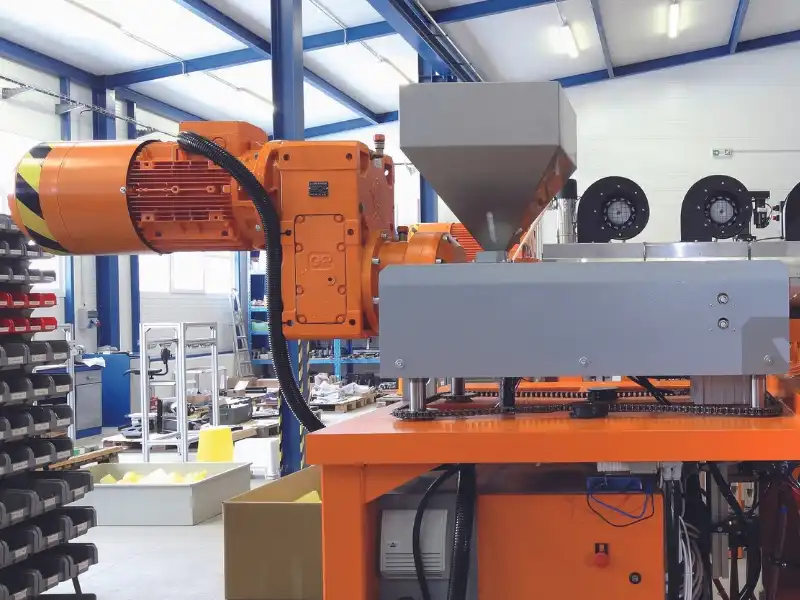

This series of motors can drive various general machinery such as compressors, ventilators, water pumps, cutting machine tools, transportation machinery and other machinery. They are widely used as prime movers in various industrial and mining enterprises such as power stations, water plants, petrochemicals, and mines.

Frame Size

H315-1000

Output

160 -10000 KW

Frequency

5-60Hz

Voltage

3000V-11000 V

- 5~60Hz

- Box-type structure, light weight and good rigidity.

- Vacuum Pressure Impregnation (VPI) Class F Solvent-free Paint Treatment

- The loss is reduced by 20% based on the IEC34-1 standard

- Select high-quality steel to weld into an integral square box

- Closed cage rotor three-phase asynchronous motor.

- Low loss silicon steel sheet

- The bearing adopts end cover type spherical sliding bearing.

- Anti-corona coil design

- The motor can be started directly at low frequency with load

- Torque smoothing at low speeds

This product is available in several variations. Contact us to discuss your exact requirements.

Customize Your Motors

We can customize the motor for you according to your working conditions.

- Corona protection at altitudes of 1000 meters and above

- IP55 Protection

- Double shaft

- SKF bearings

- W outdoor, F indoor anti-corrosion, WF outdoor anti-corrosion

- YTM

- Frame size is above H630

- Frame Size: H500 with thrust sliding bearing

- The motor with electric heater

- The motor with Current Transformer

Notice for Ordering

Basic conditions for normal operation of TEAAC IC666 High Voltage Variable Frequency AC Induction Motor:

- Altitude not exceeding 1000m

- The maximum ambient air temperature shall not exceed 40°C; the minimum ambient air temperature shall be -15°C for motors with rolling bearings and 5°C for motors with sliding bearings;

- The power frequency is 50Hz±l%

- The operating voltage variation range is not greater than the rated voltage ±5%

- The motor is rated for continuous duty S1

Applications

The Industrial Fan

A industrial fan is a machine that relies on input mechanical energy to increase gas pressure and discharge gas. It is a driven fluid machine.

The Water Pumps

A water pump is a machine that transports liquids or pressurizes liquids. It is mainly used to transport liquids including water, oil, acid and alkali liquids, emulsions, suspensions and liquid metals.

The Mining Machines

Mining machinery is the machinery directly used for mineral mining and mineral separation, including mining machinery and mineral separation machinery.

The Paper making Machinery

Paper making machinery refers to machinery that includes raw material preparation, pulping, paper making, and making finished rolls or flat sheets, as well as processing paper and paperboard.

The Chemical Machinery

Chemical machinery can be roughly divided into: grinding series (sand mill, colloid mill, ball mill, three-roller grinder, etc.); complete sets of coating equipment; kneading series; stirring and dispersing series; reaction series; emulsifying series; mixing series; dry powder mortar equipment; filtration series, etc.

Advantages

High Power Efficiency

Fast Delivery

Wide range of applications

Complete range of motors

Key Points You Need To Know About the High Voltage AC Induction Motor

Table of Content

CHAPTER ONE

What is TEAAC IC666 High Voltage Variable Frequency AC Induction Motor

TEAAC IC666 three-phase asynchronous variable frequency speed regulating high voltage motor is a new generation variable frequency speed regulating motor designed and developed by LUPMOTORS to meet different market needs (mainly in special cases or working conditions with heavy loads).

It is made of new materials and new processes, and has the advantages of beautiful appearance, small impact on the environment, wide speed regulation range, convenient installation and maintenance, and reliable operation.

The motor uses advanced electromagnetic analysis software to calculate and screen electromagnetic schemes at multiple frequency points, so that the motor has a higher low-frequency starting torque.

The motor can be directly started at low frequency with load, and the low-frequency starting torque is greater than 1.5 times the rated torque of the motor.

The torque is smooth and there is no creeping phenomenon when running at low speed; it adopts a novel end cover insulation structure and a new lathless belt insulation process.

The end cover bearing chamber is insulated to achieve the effect of motor bearing insulation, which can effectively prevent the harm of shaft current caused by variable frequency power supply to the motor.

Compared with imported insulating bearings, it has better cost performance.

In addition, the voltage of the frequency converter can be increased to ensure that the motor outputs rated torque at 5 Hz without causing the motor to burn out due to heat.

This series of frequency converter motors adopts a specially designed electromagnetic scheme and reasonable stator and rotor slot matching, which can adapt to various conditions of frequency converter power supply, so that the motor can output constant torque at low speed and maintain a certain overload capacity in the high frequency band.

The electromagnetic wire and insulation materials adopt reliable impregnation process and detection measures, so that the motor has a strong adaptability to overvoltage caused by the high-frequency carrier of the frequency converter.

The variable frequency speed regulation three-phase asynchronous high-voltage motor uses the frequency converter as power supply, which simplifies the equipment, saves investment, and reduces energy consumption.

The motor protection level is IP44 or IP54, and can be treated with anti-corrosion and anti-mildew technology to derive outdoor (W) and outdoor anti-corrosion (WF) motors.

Are your working condition in large loading?

LUPMOTORS offers high voltage variable frequency motors, which are suitable for your working conditions. – Please contact us freely.

CHAPTER TWO

Basic concepts and working principles of variable frequency motors

1. Basic concept of variable frequency motor The variable frequency motor adopts the AC speed regulation method of “special variable frequency induction motor + inverter”, which greatly improves the degree of mechanical automation and production efficiency, miniaturizes equipment and increases comfort. It is currently replacing traditional mechanical speed regulation and DC speed regulation schemes.

2. Manufacturing principle of variable frequency motor

1. Electromagnetic design of variable frequency motor For ordinary asynchronous motors, the main performance parameters considered in the design are overload capacity, starting performance, efficiency and power factor. For variable frequency motors, since the critical slip rate is inversely proportional to the power supply frequency, it can be started directly when the critical slip rate is close to 1. Therefore, overload capacity and starting performance no longer need to be considered too much, and the key problem to be solved is how to improve the motor’s adaptability to non-sinusoidal power supply. The methods are generally as follows:

1) Reduce the stator and rotor resistance as much as possible. Reducing the stator resistance can reduce the fundamental wave copper loss to compensate for the increase in copper loss caused by high-order harmonics

2) In order to suppress high-order harmonics in the current, the inductance of the motor needs to be appropriately increased. However, the larger the rotor slot leakage reactance, the greater the skin effect, and the higher harmonic copper loss. Therefore, the size of the motor leakage reactance should take into account the rationality of the impedance matching in the entire speed regulation range.

3) The main magnetic circuit of the variable frequency motor is generally designed to be unsaturated. First, it is considered that high-order harmonics will deepen the magnetic circuit saturation, and second, it is considered that at low frequency, the output voltage of the inverter should be appropriately increased in order to increase the output torque.

2. Variable frequency motor structure design When designing the variable frequency motor structure, the main consideration is the impact of non-sinusoidal power supply characteristics on the insulation structure, vibration, noise cooling method and other aspects of the variable frequency motor. Generally, the following issues should be paid attention to:

1) Insulation level, generally F level or higher, strengthen the insulation to the ground and the insulation strength of the wire turns, and especially consider the ability of the insulation to withstand impulse voltage.

2) For the vibration and noise problems of the motor, the rigidity of the motor components and the whole should be fully considered, and its natural frequency should be increased as much as possible to avoid resonance with each force wave.

3) Cooling method: generally forced ventilation cooling is adopted, that is, the main motor cooling fan is driven by an independent motor.

4) Measures to prevent shaft current: Bearing insulation measures should be adopted for motors with a capacity of more than 160KW. Mainly, it is easy to produce magnetic circuit asymmetry, which will also generate shaft current. When the current generated by other high-frequency components is combined, the shaft current will increase greatly, resulting in bearing damage, so insulation measures are generally required.

5) For constant power variable frequency motors, when the speed exceeds 3000r/min, special high-temperature resistant grease should be used to compensate for the temperature increase of the bearing.

Are you looking for some tips of industrial motor maintenance?

LUPMOTORS’ specialist will help you – Please contact us freely.

Learn More From FAQs

You’ll find yourself working in a true partnership, resulting in an incredible experience and a competitive end products.

We are a professional manufacturer that produces and sells a variety of motors.

No. We can accept an order just for 1 motor.

For all our customers, they may have different technical requirements, such as power, voltage, type, etc. The price also varies according to different order quantities. Therefore, it is really difficult for us to provide a price list. If you can share your detailed specifications and order quantity, we will provide the price to you.

We can provide both FOB and CIF prices.

Contact Us

Consult your motor expert

LUPMOTORS is your best choice!