IEC Electric AC Industrial Motors

Your Online Solution for Industrial Electric Motors

LUPMOTORS offers a comprehensive range of three-phase induction AC motors, customized to meet the diverse needs of various industries and applications. Whether you're in manufacturing, processing, or any other sector, our motors deliver reliable performance and efficiency.

IE4 Series Low Voltage Motor

- LUPMOTORS IE4 motors, known as Super Premium Efficiency Motors, are crafted using advanced materials around standard three-phase motors.

- Our motors are ideal for a wide range of industrial applications.

- Developed in line with energy-saving standards from IEC (IEC/EN 60034-30-1:2014) and approved by BIS under the latest IS 12615, our IE4 motors provide significant energy savings, lower operating costs, and reduced carbon emissions to help meet pollution regulations.

- Operating two efficiency bands above IE3 motors, IE4 motors reduce energy losses by nearly 20%.

- Our motors are particularly recommended for applications where motors run almost continuously at full load, ensuring optimal performance and efficiency.

LUPMOTORS: Customized Three-Phase electric motors for sale to Meet Your Demands.

Supplying specifically to the needs of large companies, factory buyers, and electric motor distributors, we specialize in three-phase induction AC motors, customized to both specialized and general industrial applications. At LUPMOTORS, we don’t just meet your expectations – we custom-engineer solutions to fit your precise requirements!

Application

industrial, for pumps, for lawn-mowers, for floor scrubbers, for furniture level adjustment, for drills, for dryers, cooling tower, optical, for refrigerators, solar, for the mining industry, for automatic doors, smoke extractor, conveyor, for boat, for medical equipment, for Venetian blinds, blower, for water pumps, for table height adjustment, for winding operations, for crane, for power tools, for frequent stop/start applications, parking brake, for microscope focus, for roller mills, for furnaces and ovens, for washdown applications, for elevators, for railway applications, packaging machine, for rotary tables, for smoke and heat exhaust ventilation systems, for compressors, agricultural, linear actuator, for hair dryers, for vacuum pumps, for wind turbine, oil & gas rigs, for vacuum pump braking, centrifuge, heavy-duty, maritime industry, mill duty, for automatic distributors, for the automotive industry, for robotics, for conveyors, for lifting applications, for agribusiness, high-temperature, for measurement instruments, for the textile industry, spindle, for medical applications, for cutting machine, for the chemical industry, for hydraulic applications, food, oil pump, for the semiconductor industry, for crusher, for wood-processing machines, for electric screwdrivers, for electric vehicles, for sewing machines, retrofitting, wind turbine yaw, for electrohydraulic brake, for fitness equipment, for centrifugal pumps, propulsion, for wheelchair, for the oil and gas industry, for AMT gearbox actuator, for winches, for water treatment applications, for household appliances, for air compressors, for massage equipment, for spray gun, for the electronics industry, for power steering, for machine tools, for blinds, for electrical apparatuses, for electric powertrains, for forming machines, for grinding machines, for atmospheres containing explosive dust, for military applications, for turbocharger, for fans

| Standard | IEC60034-30-1 |

| Frame Size | H80-450MM |

| Rated Power | 0.75KW-1000KW |

| Degrees or Energy Efficiency | IE4 |

| Voltage and Frequency | 400V/50Hz |

| Degrees of Protections | IP55 |

| Degrees of insulation/Temperature rise | F/B |

| Installation Method | B3、B5、B35、V1 |

| Ambient temperature | -15°C ~+40°C |

| Relative humidity should be less than 90% | |

| Altitude should be lower than 1000 m above sea level | |

| Cooling Method | IC411、IC416、IC418、IC410 |

- Frame:H80~H450

- Rated power:380V/ 415V/ 460V/ 490V/ 660V/ 690V

- Rated frequency:50HZ/ 60HZ

- Speed:3000rpm, 1500rpm, 1000rpm, 750rpm

- Power scope:0.37~1000KW

- Mounting:IMB3/ IMB5/ IMB35/ IMV1

- Protection class:IP55

- Cooling type:IC411

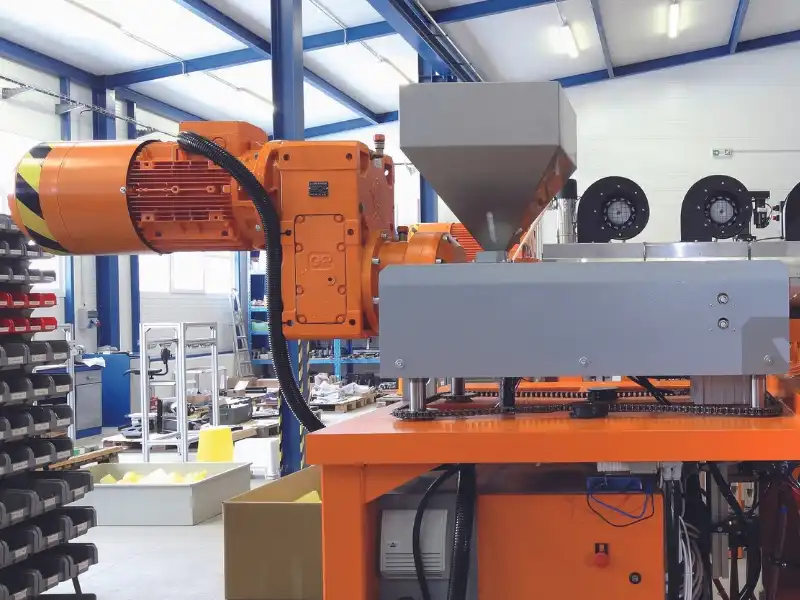

LUPMOTORS AC Industrial Motors for Your Industrial Facilities

Reliable and Cost-Effective Three-Phase Induction AC Motors for Heavy-Duty Operations in Cement Plants.

Robust Solutions for Cement Plant Machinery

In cement plants, heavy-duty process equipment and machinery such as mixers, agitators, belt conveyors, stacker-reclaimers, and cyclone filters are essential. These machines rely on large, robust motors and gearboxes. Given the continuous operation of cement plants, even minimal downtime is unacceptable. Hence, the need for highly reliable motors like LUPMOTORS’ three-phase induction AC motors.

LUPMOTORS’ energy-efficient motors (IE2, IE3, and IE4) can dramatically lower electricity consumption, thereby cutting down on operating costs. Additionally, the dusty environment in cement plants demands motors with specialized enclosures and durable designs. Our motors come equipped with these features, ensuring optimal performance even under harsh conditions.

General Purpose AC Industrial Motors

General Purpose Motors

Our three-phase IEC metric general purpose AC motors operate on three-phase AC power, eliminating the need for capacitors to start or run. These motors provide higher torque and greater efficiency compared to single-phase models with the same horsepower (HP), revolutions per minute (rpm), and frame size.

Designed to meet a standard set of electrical, dimensional, and performance requirements based on kilowatt (kW) ratings, these motors feature metric dimensions. They are widely used outside the U.S. to power compressors, conveyors, fans, and pumps that adhere to International Electrotechnical Commission (IEC) electrical standards.

Our motors typically have a single protrusion on the motor shell, such as a conduit box, which houses the electrical connections between external power cables and the motor’s internal wiring.

Ensure Uninterrupted Operation and Energy Efficiency with Our Three-Phase Induction AC Motors.

Sugar Mills

The process of converting sugarcane into sugar is intricate, requiring heavy-duty equipment and machinery such as cranes, conveyors, washers, crushers, stirrers, boilers, sieves, packaging machines, and portable conveyors/loaders. These machines consume significant amounts of energy, making the use of energy-efficient motors essential to reduce production costs per tonnage.

During peak season, sugar mills must operate continuously, necessitating highly reliable machinery. A single workstation failure can compromise the entire production batch. The reliability of plant operations hinges on the quality of motors used in the equipment and process machinery.

LUPMOTORS are renowned in the sugar industry for their superior performance, exceptional energy efficiency, and prompt after-sales service. For over 25 years, we have been supplying top-quality three-phase induction AC motors to various sugar mills, ensuring smooth and cost-effective operations.

Customized Solutions for Specialized Needs with the Added Benefit of Energy Savings.

Textile Mill

Textile mills rely heavily on motors for spinning and weaving machines, often operating in dust and fluff-laden environments. Designing electric motors for these conditions requires special attention to ensure optimal performance.

LUPMOTORS has developed three-phase induction AC motors with specialized enclosures, allowing seamless operation even in fluff-laden settings. Our motors feature a uniquely designed fan cover that ensures efficient cooling while preventing fluff and dust from entering. Our energy-efficient textile motors (IE2, IE3, and IE4) offer significant power-saving benefits.

LUPMOTORS’ textile motors are also known for their minimal maintenance needs and long life, providing a lower total cost of ownership compared to other motors. Our motors deliver exceptional value for money, making them an ideal choice for textile mills.

For Unmatched Performance in Demanding Conditions, Choose Our Robust Electric Motors.

Steel Plants

Steel plants operate in high ambient temperatures and aggressive environments, necessitating electric motors with special construction features. These motors must also function continuously under these tough conditions.

LUPMOTORS’ roller table motors are versatile, customized solutions designed for superior performance, durability, and energy savings in steel mills. They can withstand high torque and sudden torque variations common in steel plant operations and operate at the higher speeds required. Our roller table motors are available in premium efficiency versions, including IE3 and IE4, and are easily controlled using Variable Frequency Drives (VFD).

For years, we have been supplying roller table and other types of motors to various steel plants, ensuring robust and efficient operations.

Reliable Range of LT Motors, Manufactured in a World-Class Facility and Approved by NTPC.

Power Plants

In today’s industrialized world, power is the driving force behind almost everything. Power plants must operate 24/7, meaning every piece of machinery must deliver peak performance and uninterrupted operations.

Three-phase induction AC motors have numerous applications in power plants:

- Thermal Power Plants: Used in bulk conveyors, wagon unloaders, boiler pumps, and slurry pumps.

- Hydroelectric Plants: Operate large gates and guide vanes in turbines.

- Wind Energy: Turn the direction of the nacelle.

- Nuclear Plants: Power cooling pumps and feed water pumps.

- Solar Energy: Cool power electronics in inverters using pumps or electric fans, and adjust the direction of solar panels.

Power plants typically require an LT range of electric motors up to 450 kW for various purposes. LUPMOTORS is proud to be one of the first manufacturers to receive approval from NTPC (National Thermal Power Corporation Limited) for our LT range up to 450 kW. This approval reflects our state-of-the-art manufacturing facilities, commitment to the highest quality standards, and adherence to world-class manufacturing practices.

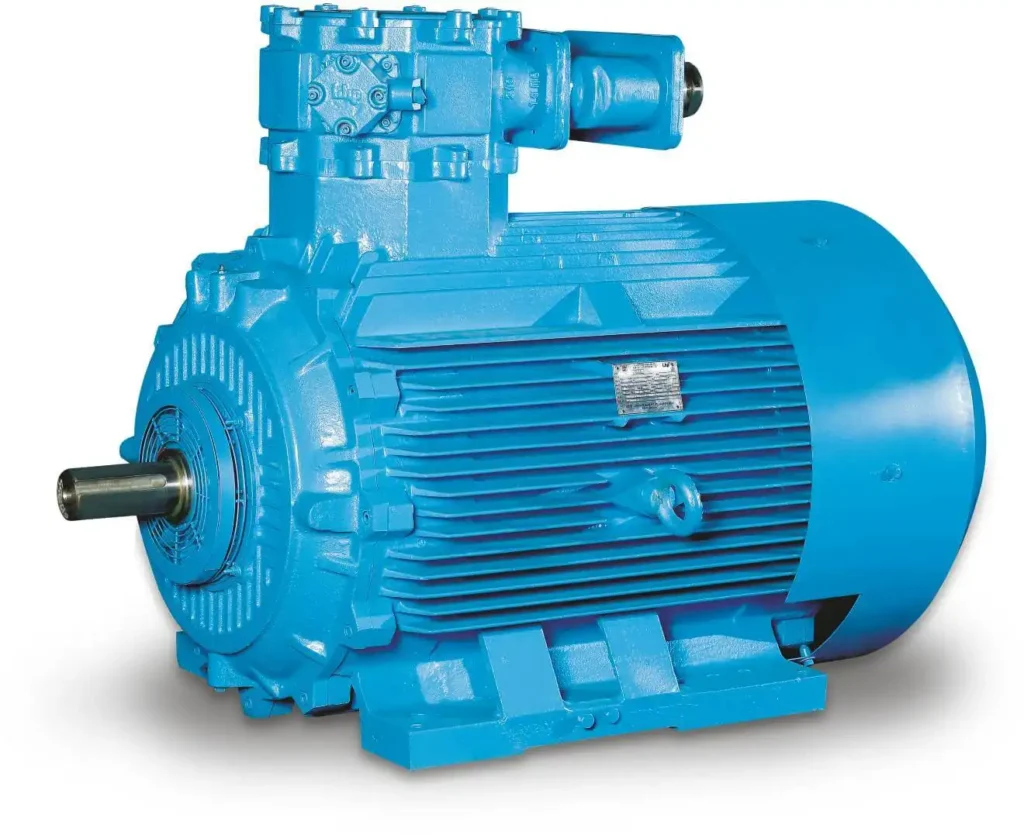

Safe and Reliable Electric Motors for Explosive Environments on Offshore Platforms and Oil Refineries.

Oil & Gas

Offshore platforms and oil refineries utilize complex machinery spread over extensive areas. These environments are filled with volatile, explosive gases and petroleum fumes, making them highly susceptible to explosions.

An explosion can occur when three elements—combustible matter (e.g., petroleum fumes), oxygen, and an ignition source (e.g., an electric spark)—come together. This scenario is common in oil and gas plants, necessitating the use of specially designed equipment to prevent ignition sources.

Our range of non-sparking, flame-proof, and increased-safety electric motors are designed with these risks in mind. Certified by ATEX, IECEx, BIS, and PESO, our motors are ideally suited for the oil and gas sector, ensuring safety and reliability in hazardous environments.

Experience robust performance and long service intervals with our motors, specifically designed for demanding outdoor environments.

Construction

Construction machinery, such as crushers, concrete mixers, tower cranes, goods lifts, and passenger hoists, are vital to various construction projects. These machines are typically electrically powered, making electric motors essential. The extreme working conditions and rugged usage on construction sites demand robust and reliable equipment.

LUPMOTORS’ electric motors are the preferred choice for many leading companies in the construction sector. Our motors are designed to deliver peak performance and withstand long, continuous working hours. Construction equipment consumes a lot of power, and using our dependable, energy-efficient three-phase induction AC motors (IE2, IE3, & IE4) can lead to significant power savings while ensuring trouble-free performance.

The Pain Points for Your Selecting AC Industrial Motors for Your Industrial Facilities

1.Inconsistent Motor Performance

LUPMOTORS ensures each motor is engineered with precision and made from high-quality materials, guaranteeing peak performance and minimizing downtime.The Lifespan for LUPMOTORS’ AC MOTORS is at least 10 years.

2.High Energy Consumption

Problem: Many industrial applications require motors that operate continuously, leading to high energy consumption and costs.

Solution: Emphasize the energy efficiency ratings of your motors, such as IE3 or IE4, and explain how these can lead to significant cost savings over the lifecycle of the motor.

3.Overheating Issues

Problem: Motors often overheat due to excessive use or inadequate cooling systems, which can lead to premature wear or failure.

Solution: Highlight the design features of your motors such as enhanced cooling systems or superior thermal management technologies that prevent overheating, even under high load conditions.

4.Maintenance and Repair Costs

Frequent maintenance can interrupt your operations and lead to higher costs. Our motors are built to require minimal maintenance, making them cost-effective solutions for any industrial application.

5.Harsh Environmental Conditions

Industrial environments can be extremely harsh on equipment. LUPMOTORS’ three-phase induction motors are designed to withstand extreme conditions such as dust, moisture, and temperature fluctuations, ensuring reliable performance regardless of the environment.

6.Noise and Vibration

Problem: Excessive noise and vibration not only contribute to a disruptive environment but also indicate potential mechanical issues.

Solution: Feature motors designed with advanced vibration suppression technology and noise reduction capabilities, enhancing operational comfort and longevity.

Guarantee

Robust Seaworthy Wooden Case Packaging

Our team is always available to assist with anissues you may encounter with ourinduction AC motors. Comprehensive Information.

Optimal Quality Components: 100% Copper, Cold Rolled Steel Stator, Premium Bearings like SKF, NSK, FAG, and NTN

Factory Price with durable quality to reduce your costs for after-sale problems.

Discover firsthand the exceptional quality of LUPMOTORS' three-phase induction AC motors.

See the Quality: Our High-Res Photos of Three-Phase AC Motors Be amazed by the detailed photos of LUPMOTORS’ pre-owned three-phase AC motors. Perfect for import customers, these images showcase our motor quality at every angle. See and believe the excellence!

JB/Q Lead Wire

Tinned copper, nitrile cover, rubber insulation.high withstand voltage, high insulation, moresecure.

Stator Core

Tinned copper, nitrile cover, rubber insulation.high withstand voltage, high insulation, moresecure.

Stator Products

LUPMOTORS utilizes cutting-edge vacuum impregnation insulation techniques in our three-phase induction AC motors.

100% Copper Winding

High grade 100% copper wire, adopts doubleoverlap, manual embedded lines, high rate slotfull, and adequate material. With 155/180 leveloxygen-free copper rod, which leads to morestable current

Rotor&Bearing

Each rotor coated withanti-rust painting, makesequipment stock and uselonger time

Bearing use NSK, FAG, SKF, C&UZWZ, HRB and etc.Internationalwell known brand

Thoroughly Inspected Pre-Owned Three-Phase Induction AC Motors

LUPMOTORS offers a selection of meticulously inspected, pre-owned three-phase induction AC motors, each undergoing rigorous third-party inspections. This ensures that even our used motors meet the high standards you expect, providing a reliable and cost-effective solution for your needs. Trust in our commitment to quality and performance, even with our pre-owned inventory.

- Our extensive after-sales services encompass refurbishment, readily available replacement parts, and expert technical support, ensuring your three-phase induction AC motors maintain peak performance with minimal downtime.

- Count on us to deliver unparalleled customer service and ensure the enduring efficiency of your motors, offering you not just reliability, but also the tranquility of knowing your operations are in capable hands.

- LUPMOTORS, save valuable time and resources while enjoying the assurance of our steadfast support and expertise.

Mr. Johnny Nie

CEO of Lupmotors China

Travel to Our Three-Phase Squirrel Cage AC Electric Motor Factory

construction projects

The Industry Application of Our Customers

LUPMOTORS brand provides efficiency for various industry applications from Worldwild.

We are servicing in more than 100 countries

- info@lupmotors.com

- Tel: +86 29 87809520

- Mobile&Whatsapp: +86 18700878815

- Address:No. 159, Mingguang Road, Weiyang District, Xi'an City, China

LUPMOTORS specializes in the design and manufacturing of high-efficiency three-phase induction AC motors, catering to a broad spectrum of industrial applications worldwide. Our portfolio, recognized for its exceptional quality and reliability, spans a comprehensive range of motors that meet the rigorous demands of industrial, residential, and commercial sectors. From water treatment and energy production to the intricacies of HVAC systems and beyond, LUPMOTORS motors are engineered to enhance performance and sustainability in critical infrastructure and services. Our commitment to innovation and excellence ensures that our clients, including factory buyers and electric motor distributors in Vietnam, Pakistan, Africa, and Southeast Asia, receive products that not only lead in efficiency but also in value and operational longevity.

Catering specifically to the needs of large companies, factory buyers, and electric motor distributors, we specialize in three-phase induction AC motors, tailored to both specialized and general industrial applications.At LUPMOTORS, we don’t just meet your expectations – we custom-engineer solutions to fit your precise requirements!

Our 24/7 technical support Assurance for your after-sale Issues & technical questions.